Production of formats – COMPLETE SKIN

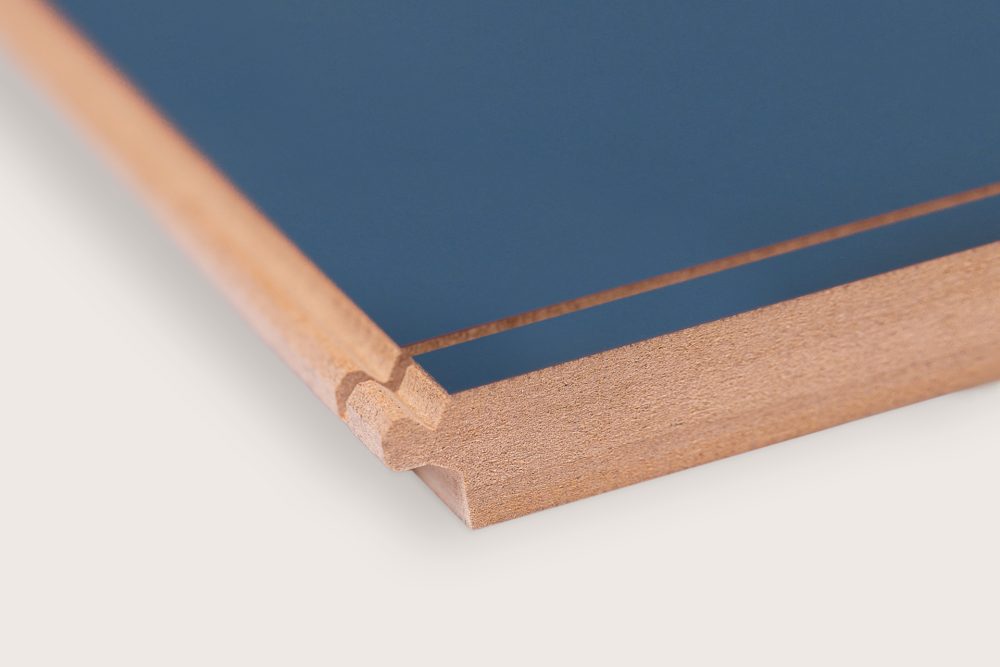

During the production stage of the furniture body, we select formats made of COMPLETE SKIN board – a material that offers high durability, aesthetics, and the possibility of precise processing. This collection includes Carbon products – winner of the Furniture Diamond award. It is characterized by a unique surface structure imitating carbon fiber weave, combining modern design, high durability, and environmental responsibility.

HOT MELT LAMINATION technology and PUR adhesives ensure increased resistance to temperature and moisture, as well as above-average surface durability. We use chipboard or MDF as a substrate, tailored to the requirements of hygiene, usability, certification (FSC®), and even flame retardancy.

Already at the production stage, we prepare elements dedicated to the Flick&Click™ system – holes, grooves, and mounting structures are milled so that assembly is quick, precise, and requires no tools.

Furniture fronts – technology that adds value

Fronts are the showcase of a piece of furniture, which is why we offer solutions that combine durability, aesthetics, and the latest technologies. We use, among others:

- MELAFOL fronts in 3D technology – milled, finished with polymer film,

- Micro Milling™ technology – ultra-precise milling of microstructures and subtle grooves that create a unique 3D effect.

- 2D fronts made of Complete Skin furniture board – durable fronts, created using technology that ensures scratch resistance, ideal for modern, minimalist forms.

By choosing fronts made with these technologies, we guarantee: a consistent design with the body, very good durability, greater added value for the end user, and ease of production at

our partner’s facility.

The patterns and colors of the boards we offer are consistent with the collections of the largest manufacturers of laminated boards, such as Egger, Kronospan, and Woodeco (formerly Pfleiderer).

Summary

Flick&Click™ technology introduces a new quality in furniture production and assembly, enabling quick, tool-free assembly of cabinets in the M45 and Corner90 systems. Thanks to a comprehensive approach—from precise design, through the production of COMPLETE SKIN formats and fronts, to final assembly—each element is perfectly matched and ready to use “at a click.” This solution reduces assembly time, eliminates errors, and allows manufacturers to focus on creating modern, functional, and perfectly refined furniture.

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist