Advanced manufacturing technology

Advanced production technologyMelaco’s furniture boards are made using modern technology and carefully selected materials, such as laminated particleboard, MDF and high-quality furniture boards covered with PET laminate. Production is carried out in the MTO (make to order) system – each project is developed individually, according to customer specifications. This allows us to offer a perfect match of dimensions, structures and finishes to a specific project.

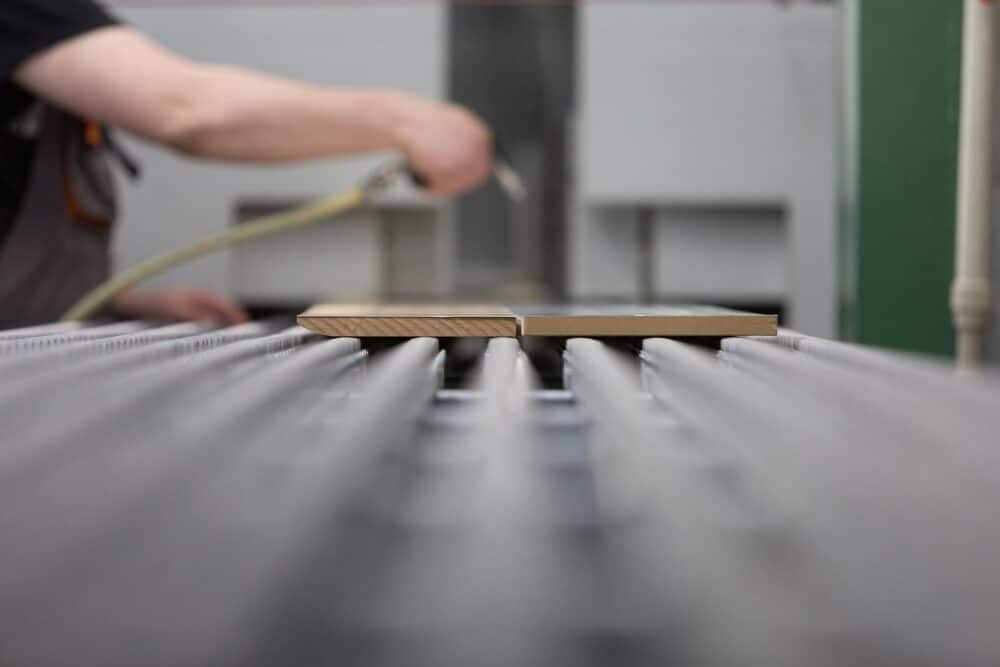

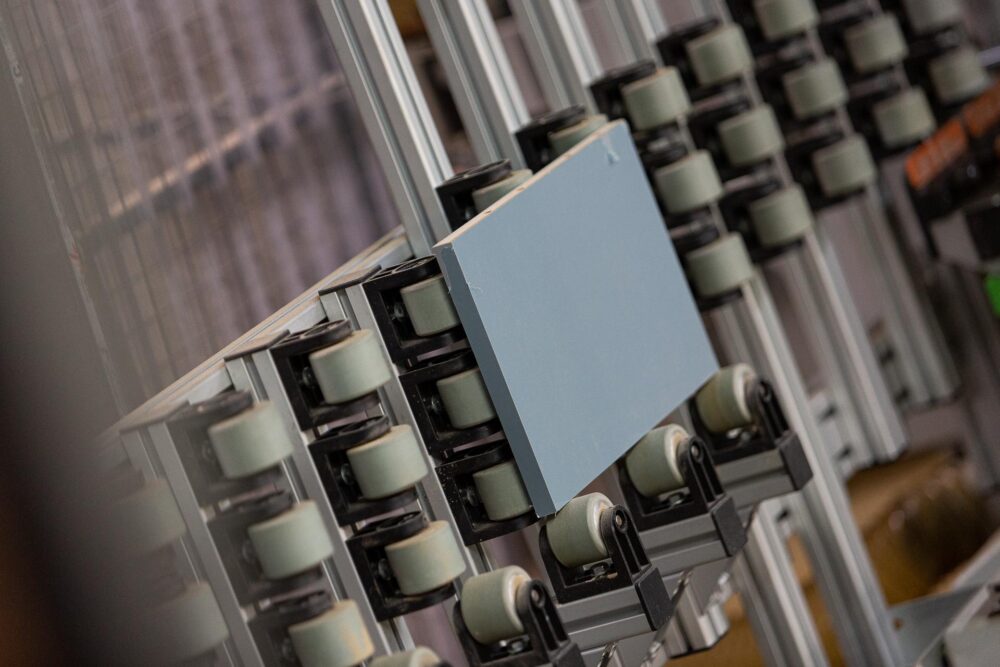

At the first stage, the components are cut on a SELCO panel center, which ensures high precision cutting, as well as the ability to work with materials with a variety of finishes – from classic laminates to supermatt and high-gloss surfaces from the COMPLETE SKIN collection. The parts then go to the BIESSE STREAM automatic formatting and edgebanding line, which allows perfect finishing of narrow planes.

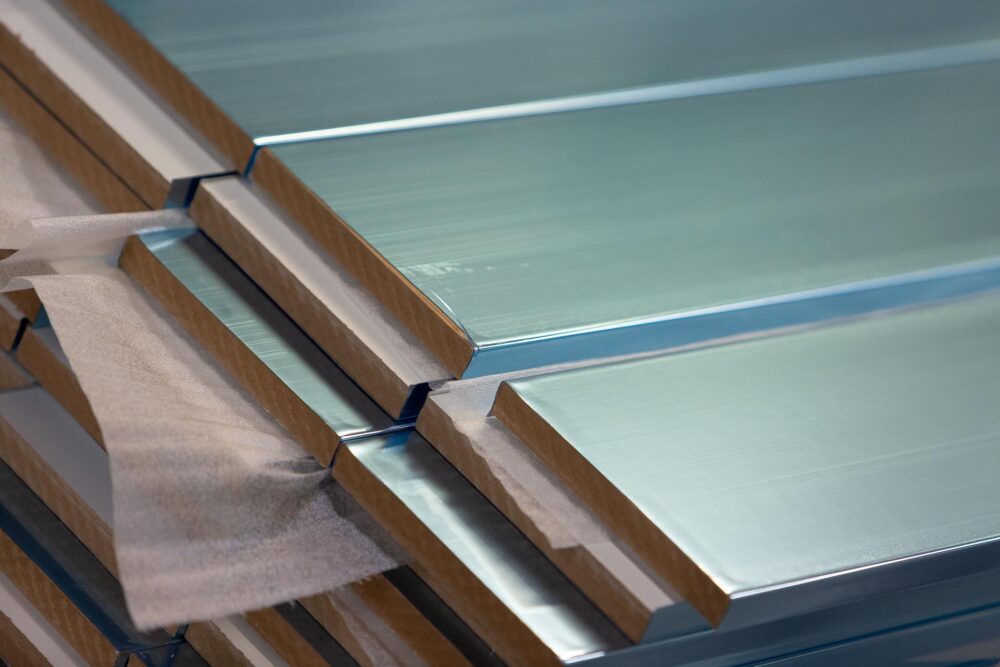

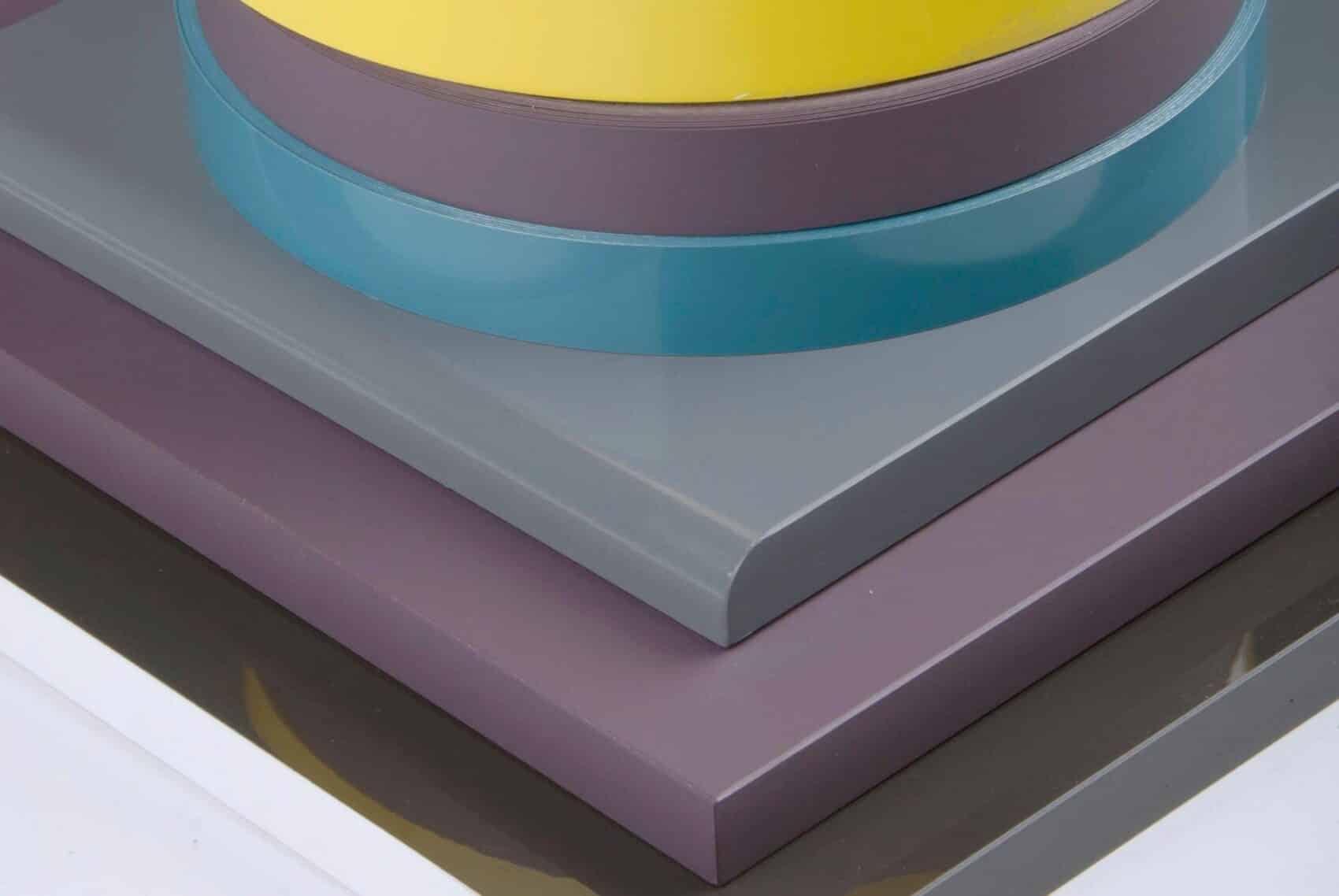

For wrapping, we use matching ABS edging with a thickness of 0.5 to 2.0 mm or identical polymer films (PET, PP, PVC) with a thickness of 0.3 to 0.6 mm both on the plane of the board and on its edges. Such a procedure allows to achieve the effect of a monolithic solid – the finished product looks like it is made of a single material and achieves an elegant 3D effect. Alternatively, we can use contrasting colors of the film on the edges, which gives additional design possibilities.

Read more about the manufacturing process of our furniture formats here →

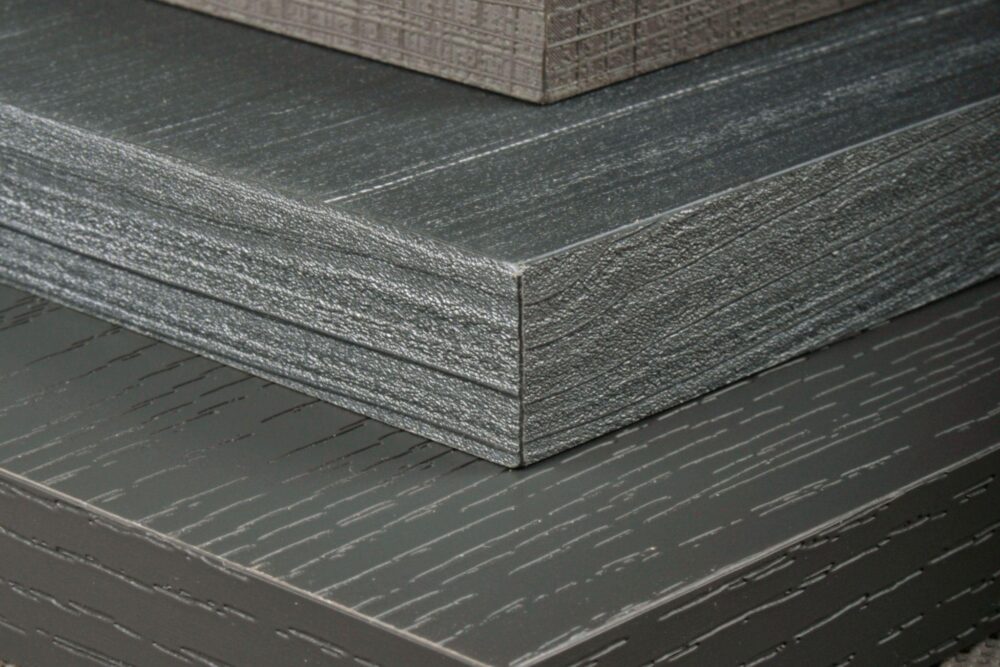

PUR glue, used in the lamination process, guarantees maximum resistance to moisture and elevated temperatures, which makes our components perfect for kitchen and bathroom furniture, among others. In addition, we use CNC technology and 3D milling, which ensure the highest precision in machining and allow us to create individual patterns and structures (e.g. Micro Milling™).

Melaco’s mouldings are used in a wide range of applications: from kitchen and bathroom furniture, to children’s, youth and living room furniture, as well as furnishings for office spaces. We use only certified wood-based materials (FSC®), while taking care to minimize our carbon footprint and material efficiency throughout the manufacturing process.

Technical parameters and personalization options

Dimensions:

- Width: 120-1200 mm (with postforming edge 120-915 mm)

- Length: 250-2700 mm

- Thickness: 10-60 mm

Base material:

- MDF or particle board (with postforming edge only MDF)

Machining and finishing:

- Can be cut, milled, drilled, veneered in narrow planes.

- Edge finishing – chamfer 25°, radius R1; R2.

- Narrow edge finishing – polymer edge PVC, PP, PET, ABS/PVC with a thickness of 0,3-2,0 mm.

- Plane finishing – melamine layer, PVC, PP, PET, ABS/AKRYL polymer film with a thickness of 0.1-0.9 mm and “FINISH” type film.

- CNC machining, 3D milling – possibility to design individual patterns and structures.

Surface finishes:

- Premier Matt, high gloss, wood or stone structures, special effects – such as metallic surfaces, mirror effect surfaces).

- Rich palette of colors and decors, including customer-dedicated collections.

Don’t have spare production capacity? We will deliver ready-made furniture formats to your company

By ordering ready-made furniture formers, our partners gain real benefits:

- Reduced production time – elements are ready for deployment without additional processing;

- Accurate manufacturing – each format is produced with attention to detail and by customer documentation;

- Flexible customization – wide range of sizes, structures and colors from the COMPLETE SKIN collection;

- Priority fulfillment – we offer fast delivery times for manufacturers who cooperate with us;

- Waste reduction and warehouse savings – precision manufacturing eliminates surplus materials and reduces the need for storage space;

- Certified quality – we use FSC® materials, low-emission wood-based panels and low-emission PUR adhesives.

Furniture fronts made of MDF board – MELAFOL

For projects requiring exceptional aesthetics, we offer MDF fronts fluted and covered with 3D film (PVC) in vacuum technology. Thanks to the flattening of the entire surface, the product acquires a consistent, monolithic appearance, which works especially well in kitchen furniture, bathroom furniture and elegant built-ins.

COMPLETE SKIN furniture boards

Melaco’s product range also includes MDF or particleboard, refined using HOT MELT LAMINATION technology, covered with PET or PVC film flat. This is a versatile solution for manufacturers who want to format components themselves or use them as a base for further processes – such as Micro Milling. The boards are available in a variety of decors and surface finishes for easy integration into different furniture collections.

Support at every stage of production

Furniture formers from Melaco are an option for manufacturers who want to focus on collection development, design and sales, entrusting the manufacture of components to a proven partner. Cooperation with us not only saves time, but also guarantees quality, timeliness and an individual approach to each project.

Focus on design and sales – we’ll take care of component manufacturing!

Want to learn more about Melaco production formats? Contact our sales representative and order a free sample.

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist