At Melaco, we understand the realities of our customers’ business. For over 30 years, we have been supporting furniture manufacturers in creating efficient and competitive product lines. Our ready-made furniture components are manufactured using modern technologies, certified materials and experience that translates into quality you can trust. In this post, we show how specific solutions from our offer have a real impact on production optimisation – from the first cut of the board to the finished body or front.

Ready-made components – real support for furniture manufacturers

Furniture manufacturing is a complex process in which not only the quality of workmanship counts, but also logistics, time and precision. Ready-made furniture components – i.e. properly prepared blanks, fronts, bodies or boards – allow manufacturers to significantly simplify and speed up this process by transferring part of the responsibility for the preparation of semi-finished products to a trusted partner. This is exactly the role played by Melaco.

Our components are manufactured using ready-to-assemble technology, which means that they reach the customer in a form optimised for further use in the production line. This eliminates many time-consuming and costly steps, such as cutting, gluing and milling, saving resources, space and valuable time.

What exactly do you gain by using ready-made components from Melaco?

Streamlined production. The components we supply are precision-made and ready for direct assembly – all you need to do is integrate them into the rest of the structure. This simplifies production processes and reduces the risk of technological errors.

Faster production times. Thanks to ready-made formats and fronts, there is no need to plan separate processing stages – the components arrive ready for use. Production runs more smoothly and faster, which is particularly important when fulfilling large or urgent orders.

Waste reduction. Precise production of components in accordance with specified dimensions and technology eliminates the need for cutting and adjustment, thus reducing material waste and positively impacting the ecological balance of production.

Warehouse savings. By ordering ready-made components, you avoid the need to store large quantities of raw plates or semi-finished products. You have exactly what you need, when you need it. This means lower inventories and better use of warehouse space.

Financial benefits. Less waste, shorter production times, reduced labour and processing costs, smaller warehouses – all this translates into real savings. What’s more, by transferring part of your work to Melaco, you don’t need to invest in additional machinery or hire new operators.

Read also: Melaco – a technology partner for demanding furniture projects →

Today, ready-made components are not just a matter of convenience – they are a strategic solution that allows furniture manufacturers to remain competitive in an increasingly demanding market. Find out what we offer our partners in this area.

What components does Melaco offer and how do they contribute to production optimisation?

Production optimisation is not just a matter of strategy – it also involves selecting the right materials and semi-finished products. At Melaco, we have been developing technologies and product lines for years that meet the specific needs of furniture manufacturers: shorter production cycles, easier assembly and guaranteed quality. Here are four types of components that really support efficient furniture production, regardless of the scale of your business.

1. MDF fronts coated with flat-profile foil – MELAFOL line

This solution is for those who are looking for a ready-made, aesthetic front with a distinctive character. MELAFOL fronts are manufactured on the basis of MDF board covered with polymer foil using vacuum pressing technology. What makes them stand out?

- The possibility of obtaining three-dimensional patterns and milling cuts – from geometric to classic,

- high resistance to scratches, temperature and moisture,

- ready for installation – no further surface treatment required.

This is an excellent option for manufacturers of living room, bathroom, kitchen and office furniture who want to introduce decorative elements without committing their own resources to milling or foiling.

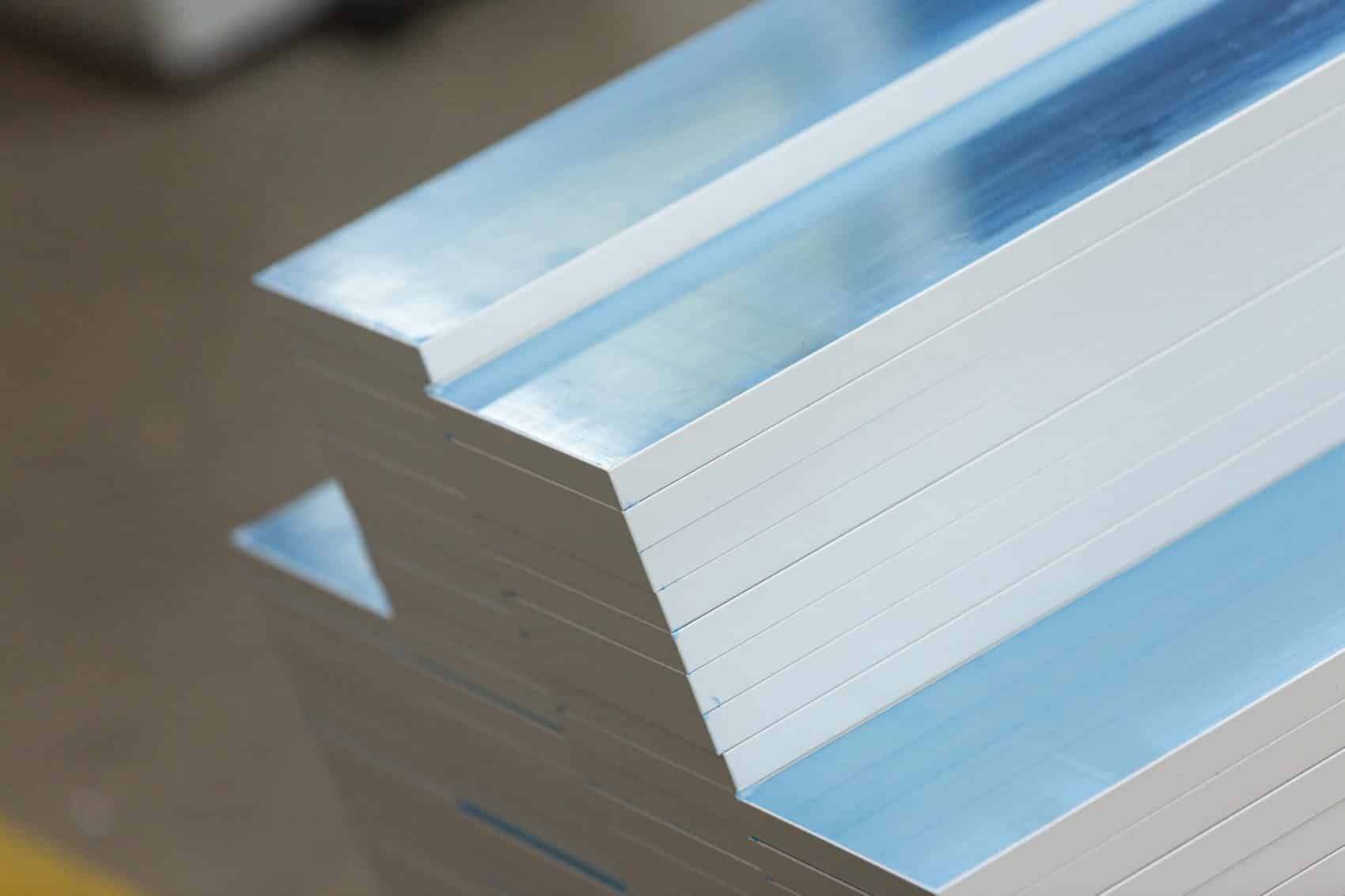

2. Complete Skin Door fronts – simple, edged

This solution combines simplicity with functionality. The fronts are made of MDF, chipboard or laminated chipboard, cut to size and finished with an edge that perfectly matches the colour of the surface.

- They are ready for immediate use on the assembly line.

- They are distinguished by their aesthetics and colour consistency thanks to the use of appropriate foils and edging,

- as well as their durability and resistance to wear and tear.

These components are ideal for manufacturers of kitchen, office, children’s and modular furniture, where speed of delivery is important while maintaining high aesthetic standards.

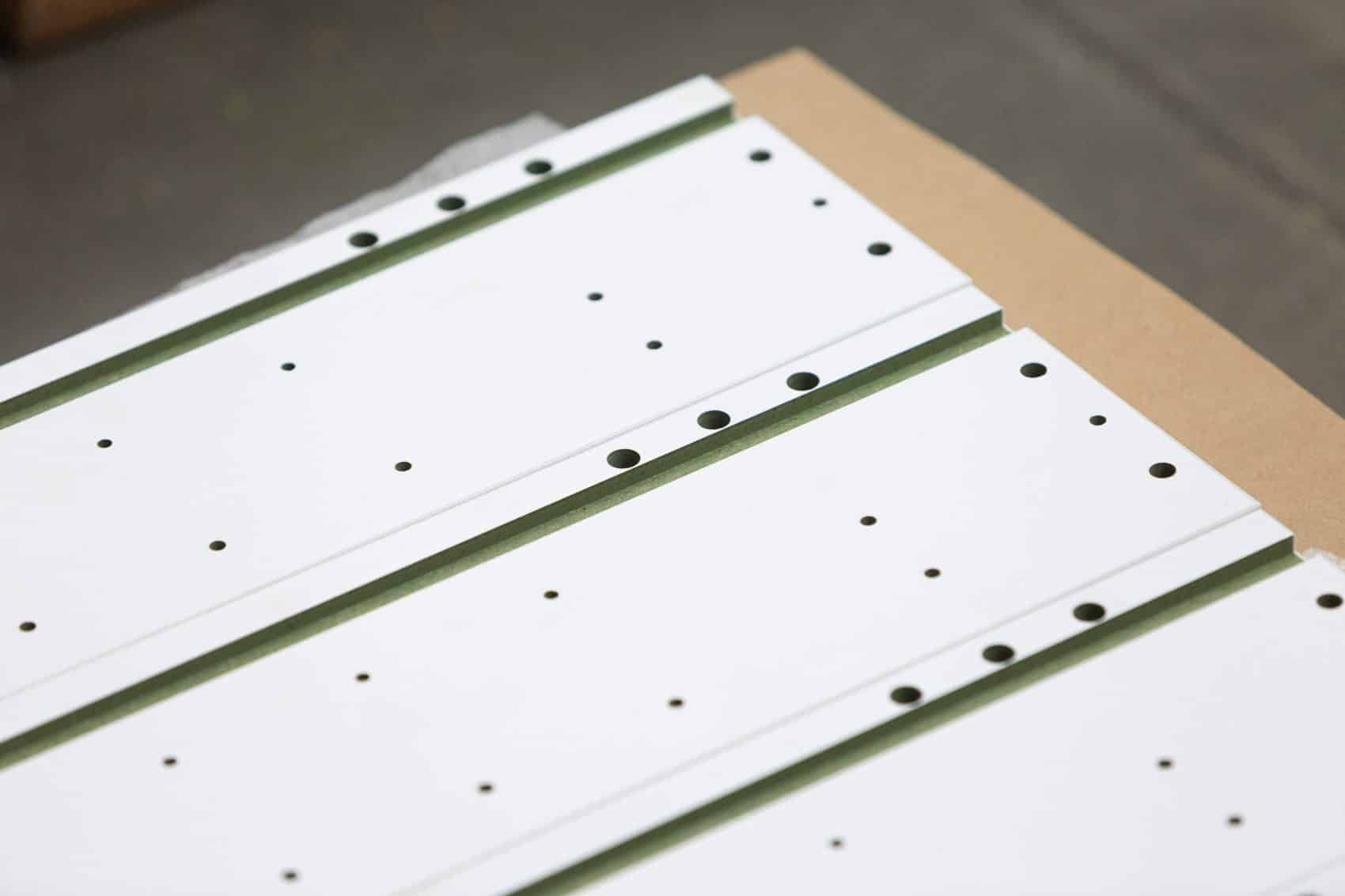

3. Complete Skin sheets – a flexible base for further processing

If your production requires customisation but you want to save time, Complete Skin boards are the ideal solution. Coated with film using Hot Melt Lamination technology, they are:

- moisture, temperature and scratch resistant,

- available in single-sided or double-sided finishes,

- easy to cut, mill and further process.

They are an excellent base for creating original fronts, front panels or decorative elements. Thanks to the use of PUR adhesives, the boards are also suitable for use in conditions of high humidity and temperature.

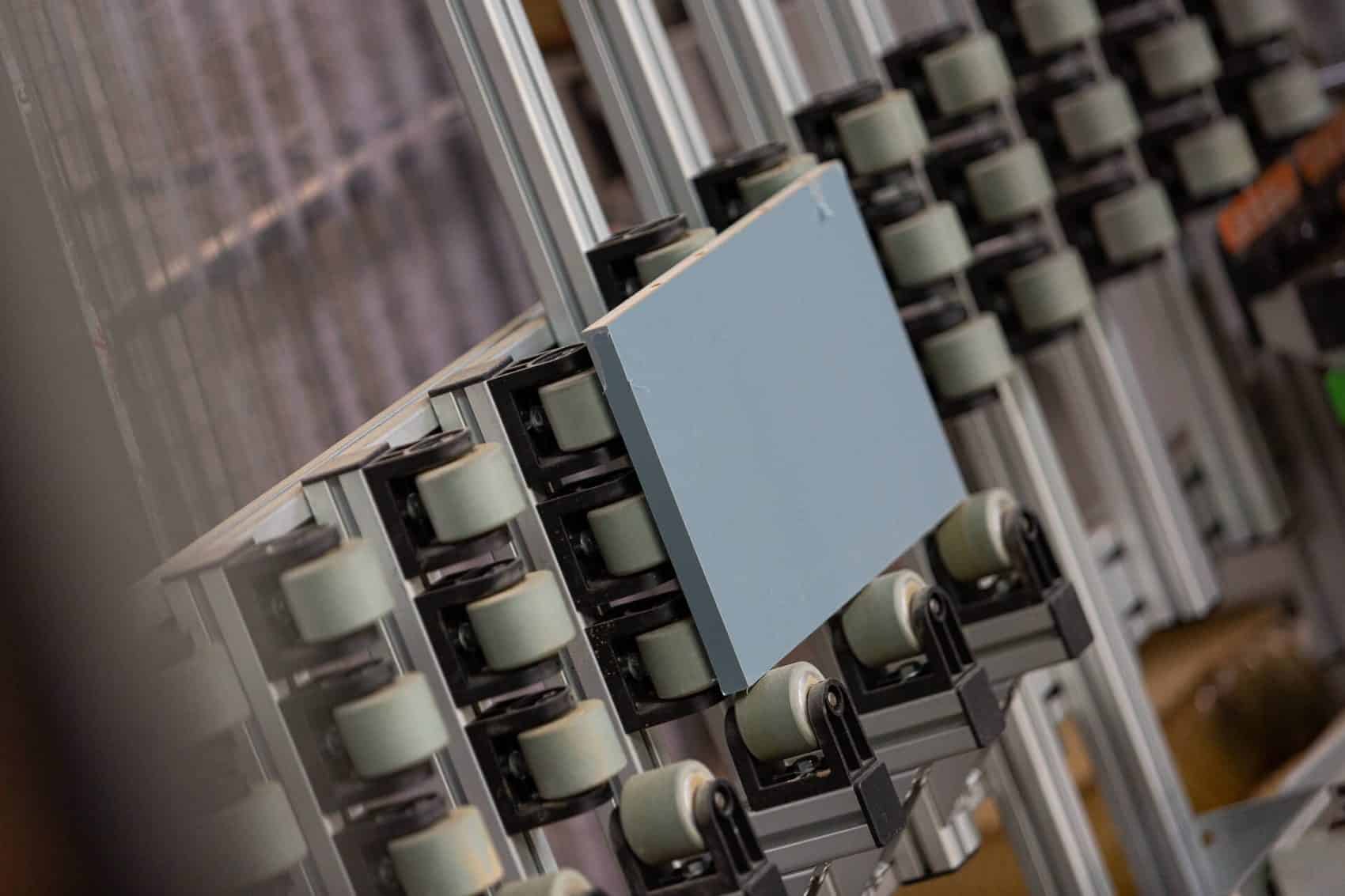

4. Complete Skin Door formats – ready-to-install components

This is the most advanced form of ready-to-use components. We offer:

- precisely cut and laminated components,

- optionally equipped with fittings,

- designed for fronts or body elements,

- option to order complete bodies ready for assembly.

Thanks to Melaco formats, manufacturers can minimise the number of operations in their own plants, reduce the need to invest in extensive machinery and shorten the production time of complete furniture.

Each of these components is created based on the individual needs of our customers – in terms of dimensions, colours and technological details.

Read also: Furniture formats – how Melaco supports manufacturers in efficient production →

Technology and quality – a guarantee of stability and precision

Modern furniture manufacturers cannot afford to compromise on the quality and repeatability of components. This is especially true when production is large-scale or just-in-time. At Melaco, we know that reliability is based not only on good materials, but also on precise technologies and control at every stage of the process.

That is why, in our daily work, we focus on advanced technological solutions that deliver measurable results in practice. They are behind the durability, aesthetics and ease of assembly of our components.

Hot Melt Lamination with PUR adhesives – durability you can trust

This technology allows for a perfect bond between the film and the board surface. At Melaco, we use PUR polyurethane adhesives, which are characterised by:

- high resistance to moisture and temperature (even near cookers and ovens),

- flexibility and durability even with intensive use of the furniture,

- no reaction to climate changes during transport, e.g. by sea.

As a result, components from the Complete Skin line are ideal for kitchens, bathrooms and commercial spaces, where durability and aesthetics go hand in hand with intensive use.

Read also: Hot Melt Lamination Technology – durable and resistant furniture →

Vacuum pressing – precision in every detail

MELAFOL fronts are manufactured using vacuum pressing technology, which allows for:

- perfect reproduction of three-dimensional milling patterns,

- precise film coverage even on difficult edges and surfaces,

- finishing of the element in three planes – without visible joints or imperfections.

As a result, 3D fronts look exceptionally aesthetic, while also being durable and ready for installation without any additional work.

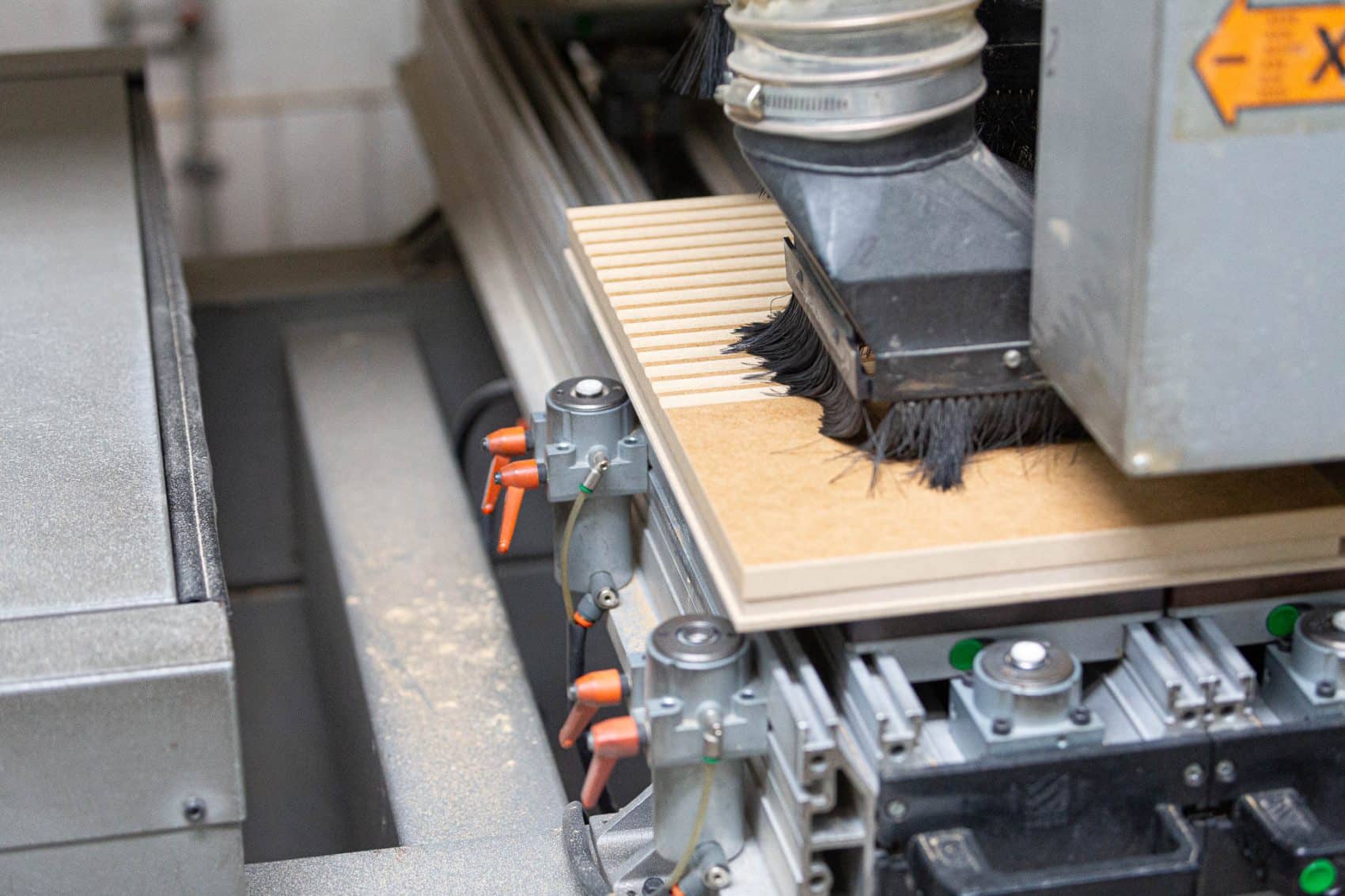

CNC machining and micro milling – customisation with serial repeatability

For customers implementing their own furniture lines or individual designs, we offer the following options:

- precise formatting and cutting of blanks on CNC machines,

- decorating foil-covered board surfaces using micro milling technology, which allows for the creation of unique graphic and structural effects.

These solutions give you complete design freedom without compromising the efficiency of the production process.

Quality control and compliance with EU standards

Every component leaving our factory meets strict standards:

- base materials are FSC® certified,

- components meet the DIN EN 16516 formaldehyde emission standard,

- surfaces are resistant to UV radiation, scratches and dirt,

- quality is monitored at every stage – from raw material selection, through the laminating process, to final formatting.

Thanks to modern technologies and strict quality control, at Melaco we can offer furniture manufacturers components that are not only ready for assembly, but above all reliable in everyday production. This is the foundation on which you can build your success.

Why Melaco? A partner for years to come

Choosing a furniture component supplier is not just a purchasing decision today – it is a strategic decision. The quality and timeliness of deliveries determine the smoothness of your production, the technology determines the durability of your products, and flexibility determines your ability to complete even the most demanding projects. That is why our customers choose Melaco not only as a supplier, but above all as a partner in the development of their business.

30 years of experience in the furniture industry

We have been present on the market for three decades. During this time, we have built not only a modern machine park, but above all relationships with our customers based on trust, flexibility and mutual development. We perfectly understand the furniture production processes and are able to respond precisely to the real needs of the industry.

A cooperation model based on individualisation and flexibility

At Melaco, we do not operate according to a rigid pattern. Each project is a separate story for us – that is why we offer:

- components made to specific orders (MTO),

- technical support during the design and implementation of a new line,

- serial or smaller batch delivery options – in line with your production rhythm,

- the possibility of ordering components with a full finish or as semi-finished products for further processing.

Sustainable development and modern production standards

We operate responsibly – we use certified wood-based panels, recycle production waste and reduce CO₂ emissions. We are part of the European Green Deal strategy, supporting our customers in building a more sustainable supply chain.

Our components meet high technological, environmental and aesthetic requirements. This allows you to offer your customers furniture that is not only functional and durable, but also manufactured in a responsible manner.

At Melaco, we combine the power of technology with a human approach to business. We are here to support furniture manufacturers, regardless of whether they are producing serial orders or original collections. Because we know that true partnership begins where standard solutions end.

Ready-made components are the future of efficient furniture production

When every hour and every detail counts, ready-made furniture components become an indispensable part of modern production. They enable shorter lead times, lower operating costs and reduced risk of errors and waste. They give you freedom in planning, space in your warehouse and stability in production – regardless of the scale of your business.

At Melaco, we design and manufacture components to provide real support for your team – ready for assembly, tailored to your technology and in line with market expectations. We offer both standard solutions and customisation options, because we know that every furniture line has a different story and every collaboration has different needs.

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist