MicroMilling™ – precision that creates a new quality of workpiece

MicroMilling™ is an advanced technology for milling the surface of furniture boards, developed for modern design and high production requirements. Unlike traditional methods of decorating fronts – based on dovetailed elements or additional machining – MicroMilling™ makes it possible to create patterns directly in the surface of a polymer film-coated board, right at the production stage.

Thanks to the use of diamond cutters and specialized CAD/CAM software (Alphacam), it is possible to reproduce even very complex structures with an accuracy of up to 50-75 micrometers. This makes it possible to realize both simple, minimalist designs and complex ornaments – with full repeatability in large batches.

Importantly, MicroMilling™ technology ensures not only aesthetics, but also durability. Milling is carried out on the surface of MDF or particleboard, covered with a polymer film. Additional use of HOT MELT polyurethane adhesive provides the surface with resistance to moisture and elevated temperatures. These features make MicroMilling™ fronts an ideal choice for spaces such as kitchens, bathrooms and dressing rooms.

What are the main advantages of this technology?

- Accuracy and repeatability – patterns are reproduced with high precision, which allows to maintain a uniform visual effect even in large orders.

- Integrated design – fronts are decorative and functional at the same time – without the need for additional assembly of components.

- Resistance and quality – thanks to the monolithic structure, the fronts are more resistant to mechanical damage and external factors.

- Optimization of production costs – MicroMilling™ technology makes using more readily available and cost-effective MDF or particleboard possible, eliminating the need for more expensive materials, such as dyed-in-place MDF. This makes it possible to reduce production costs without compromising on product quality and aesthetics.

MicroMilling™ technology is a solution for manufacturers who want to differentiate their furniture not only in terms of appearance, but also in terms of durability and workmanship. It is a modern approach to detail design – elegant, subtle and fully integrated into the form of the front.

New variants of fronts

Our new front designs are a response to the current needs of the furniture industry. Among the proposals, you can find both classic forms in a modern version, as well as bold, geometric solutions. Each design has been developed with a variety of interior styles in mind.

Classics in a modern edition

Subdued colors, such as Stone Grey or Cremona Oak Torro, combined with precise milling of the 15 mm wide frame, create elegant, modern fronts. It’s a versatile solution, ideal for kitchens, dining rooms or living room built-in – where discreet elegance and timeless style count.

Fronts made with MicroMilling™ technology – 15mm Stone Grey Supermatt frame, matching Woodeco U-16002 laminated board (old number)

Fronts made with MicroMilling™ technology – 15mm Cremona Oak Torro frame, matching Kronospan K-2738 laminated board

Geometry with character

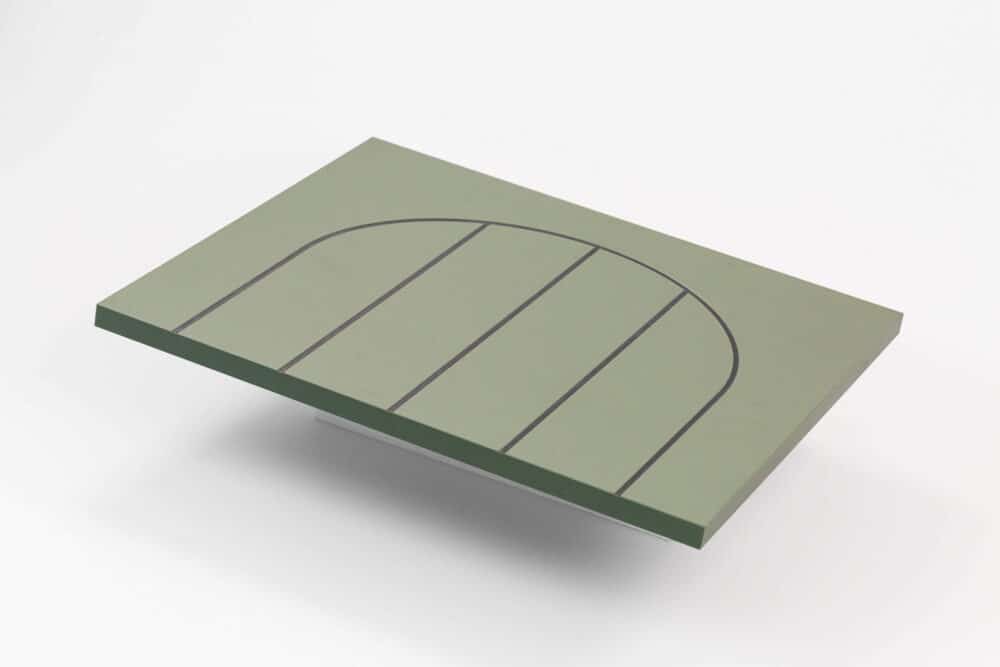

The juxtaposition of an arch with a vertical millwork brings to mind art déco aesthetics and architectural inspirations from the 1920s and 1930s. Fronts from this series are eye-catching without losing functionality. This is a choice for projects with soul – bold, but thoughtful.

Fronts made with MicroMilling™ technology – Smoke Green arc, matching Kronospan K-521 laminated board

Minimalism with a distinctive accent

Smooth fronts in shades of extinguished green and natural oak have been enriched with a milled frame only on the edge – delicate, but noticeable. This is a proposal for those who appreciate simple forms, but want to give them depth. They will work great both in the kitchen and in an office space or dressing room.

Fronts made with MicroMilling™ technology – Smoke Green edge frame, matching Kronospan K-521 laminated board

Fronts made with MicroMilling™ technology – Castella Eiche Natur edge frame, matching Egger H-1385 laminated board

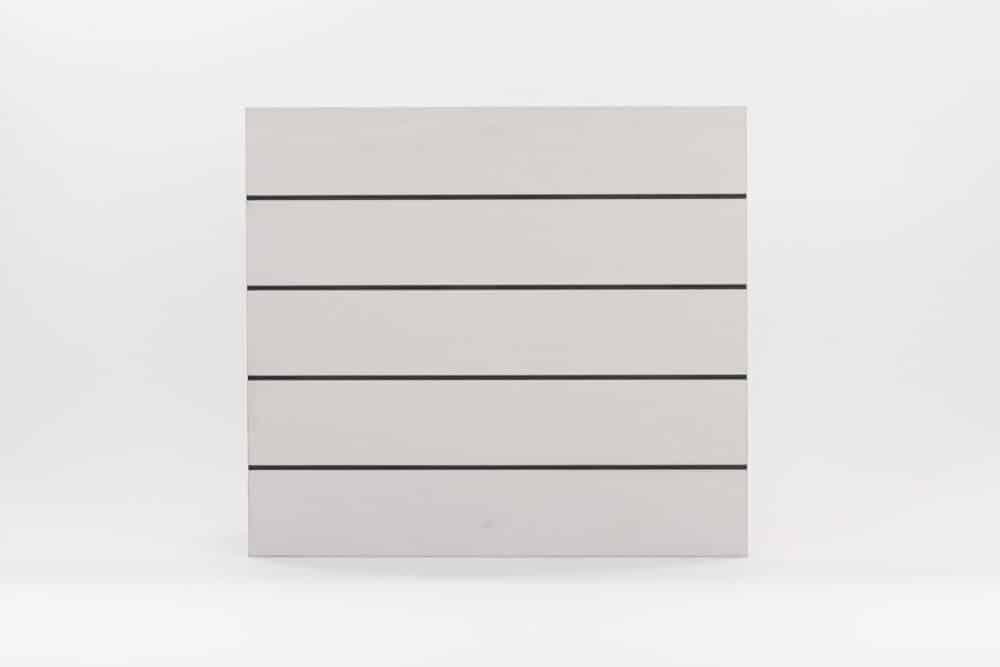

Wide laths

The new fronts with wide slats are a nod to natural structures and harmony. Available in two variants – Cashmere Paintflow with a delicate wood texture and Macadamia in a smooth version – they fit perfectly into current interior trends. Ideal for kitchen furniture collections, living room furniture and modern dressing rooms, where the pattern becomes an architectural element.

Fronts made with MicroMilling™ technology – wide laths in Macadamia color, matching Kronospan U-681 laminated board

Fronts made with MicroMilling™ technology – wide laths in Cashmere Paintflow color, matching Kronospan U-702 laminated board

Design a new collection with us

The new Melaco fronts are more than just an attractive design – they are a functional tool for creating distinctive furniture collections. Thanks to MicroMilling™ technology, you gain the opportunity to offer your customers products with unique designs and superior workmanship. Contact our sales team to select the designs best suited to your projects and together create solutions that truly impress.

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist