PUR adhesives have unique properties:

- High resistance to moisture and elevated temperatures — making them ideal for furniture components used in kitchens, bathrooms, and rooms with variable humidity.

- Durable and flexible bond — ensures durability and resistance to deformation, reducing the risk of coatings peeling off during use.

- Small amount of joint with maximum bonding strength — minimizes the visibility of the adhesive and allows for a smooth, uniform surface without excess bonding material.

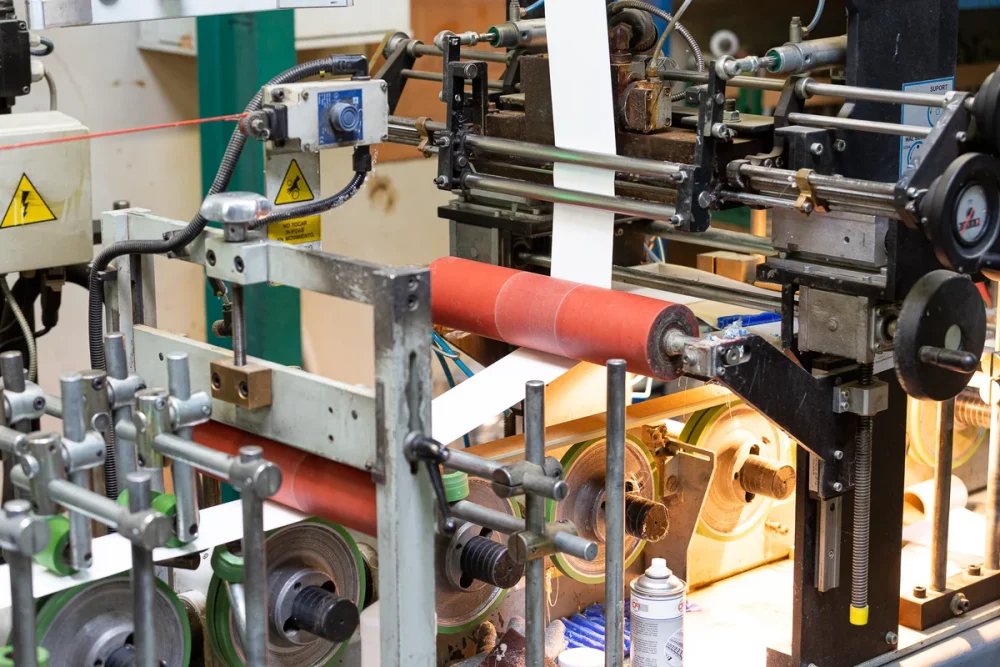

Choice of bonding technology

Although traditional adhesives used in the lamination of furniture components are usually cheaper and reduce the unit cost of production, their action is based solely on the physical process of adhesive solidification. PUR polyurethane adhesives, despite their higher purchase cost, form a bond through a chemical reaction with moisture, leading to a permanent cross-linking of the joint structure. This difference translates into more stable performance parameters and greater bond strength over a longer period of use. The use of PUR technology is therefore not a cost compromise, but a conscious technological choice that allows us to offer components of predictable and repeatable quality. This approach supports long-term relationships with customers for whom the reliability of components and the quality of workmanship have a direct impact on the durability and perception of the final furniture.

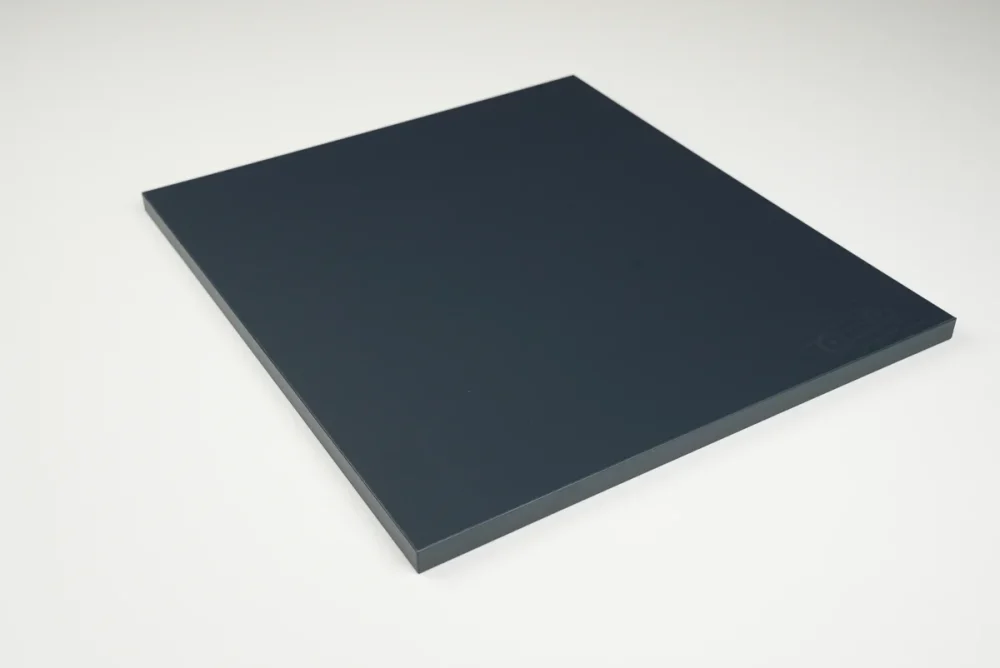

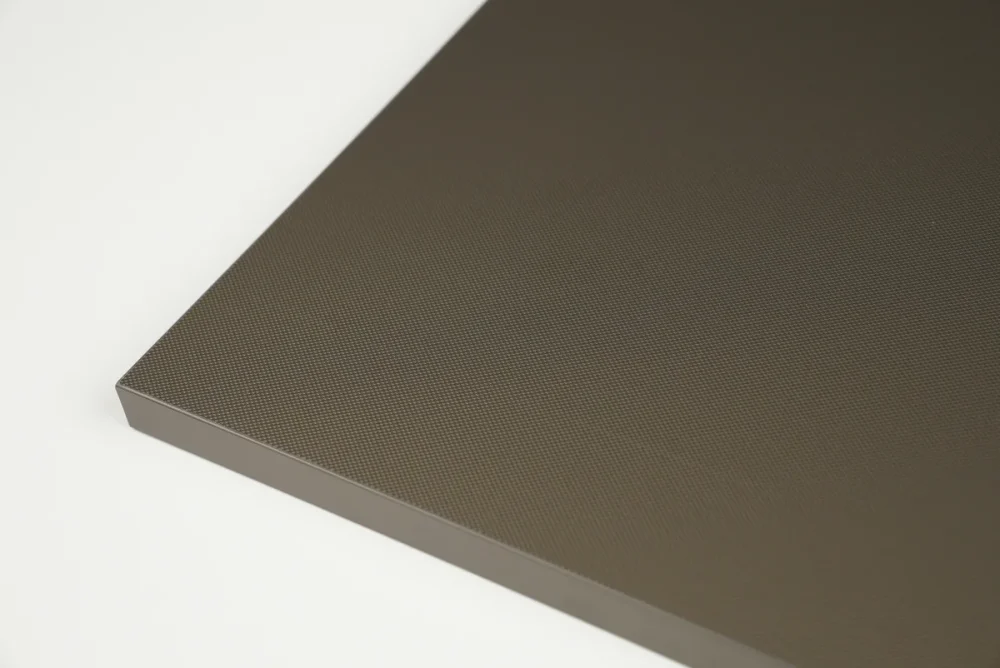

The ,,zero-joint” effect – what does it mean in practice?

In the furniture industry, there is talk of the zero-joint effect, i.e., a minimal and almost invisible joint. This effect fits perfectly with Melaco’s production philosophy. This property applies to the process of covering narrow surfaces with front edges and furniture elements. Thanks to the precise application of PUR adhesive in lamination technology:

- the adhesive joint is almost invisible – the effect is similar to laser bonding,

- the surfaces are smooth and uniform,

- the aesthetics of the finish do not interfere with the design of the furniture,

- the adhesive works invisibly but very effectively (high resistance of the adhesive joint to moisture and temperature).

This effect is particularly important in premium components, where even the smallest defect in the joint could affect the final aesthetic perception of the product.

Benefits for furniture manufacturers

The use of components manufactured using PUR technology brings real benefits to furniture manufacturers. First and foremost, it means greater durability of finished products and a lower risk of complaints related to veneer peeling or surface deformation. The uniform, smooth surface also facilitates further processing and assembly of components, and the high quality of the finish increases the aesthetic value of the final product. Thanks to the precisely controlled PUR lamination process, it is possible to maintain high repeatability of production parameters.

Summary

PUR technology in production is an important element of modern furniture component production, combining the precision of the lamination process with high technological requirements. The use of reactive polyurethane adhesives allows for stable and uniform material bonds that meet market expectations in terms of aesthetics, functionality, and reliability. The conscious choice of this technology reflects a focus on quality and the long-term value of the solutions offered, which is important for both furniture manufacturers and end users. Find out more about Cooperation with Melaco in practice. Explore examples of our implementations.

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist