3D fronts have been gaining popularity in both residential and commercial spaces for several seasons. They are a response to the growing expectations of customers who are looking for unique furniture with character and attention to detail.

In this article, we will explain what milled and vacuum-formed fronts are, why you should add them to your collection, and how technologies such as MELAFOL and MicroMilling™ allow you to take furniture design to a whole new level – without compromising on aesthetics or functionality.

What are 3D milled fronts?

3D milled fronts are furniture elements whose surface is not smooth but enriched with spatial patterns – from delicate grooves to deep, decorative embossing.

They are created by milling MDF boards and then coated using membrane vacuum technology, which accurately reproduces every line, curve and edge.

The result? A surface that comes to life – it reacts to light, invites touch and introduces rhythm and dynamism to the entire piece of furniture.

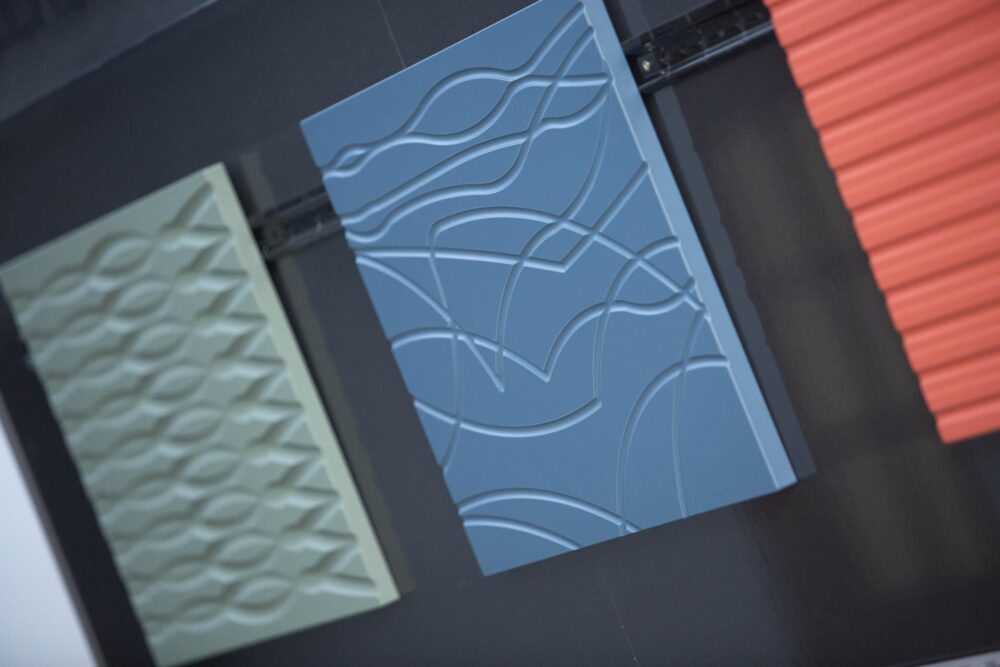

Milled 3D fronts can take various forms:

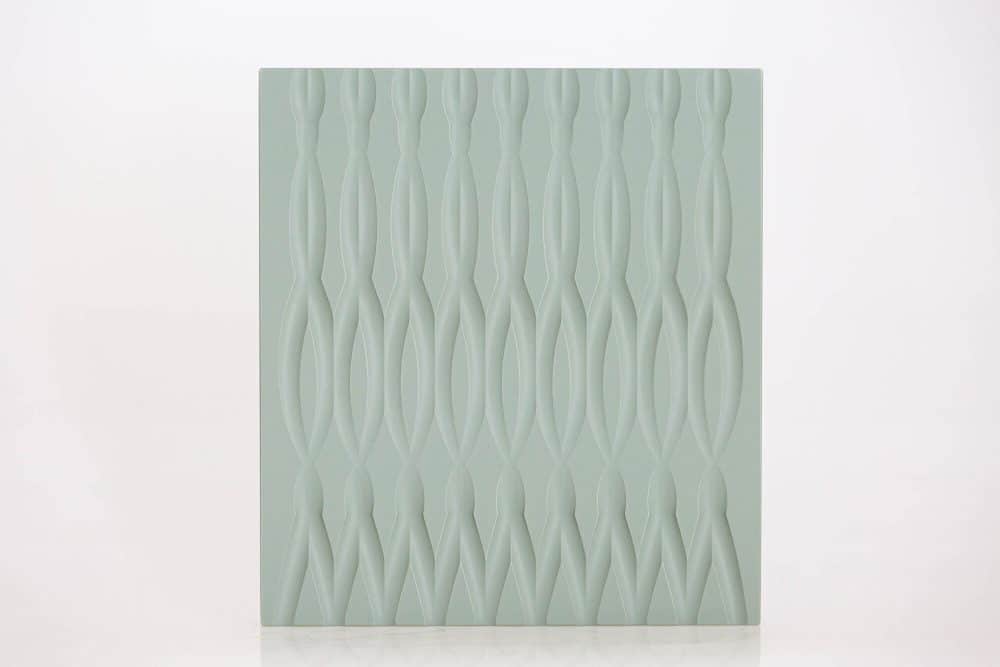

- geometric waves and structures (e.g. PEAK, PIPE FLOW),

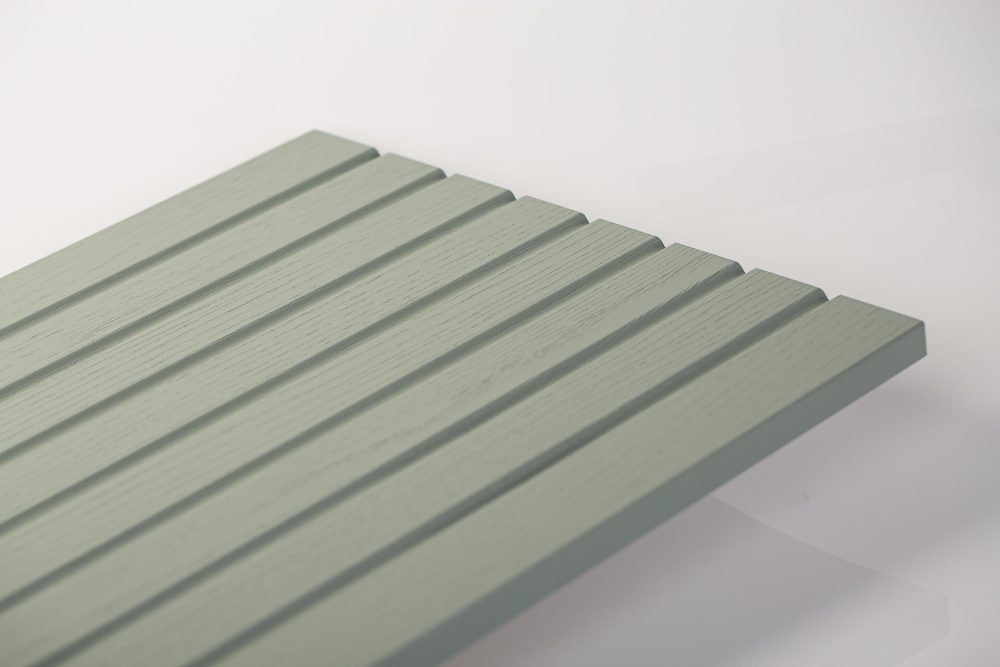

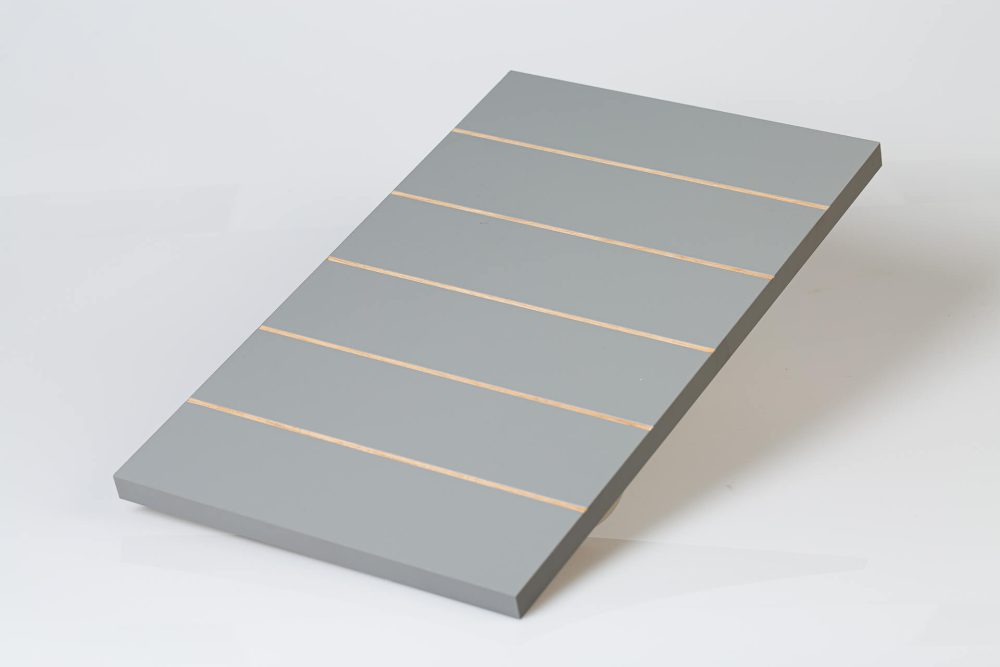

- rhythmic lamellas or grids (e.g. STRIPES, PYRAMID),

- organic wood patterns (e.g. FOREST),

- minimalist grooves and lines in the Japandi or Scandinavian style.

This solution perfectly combines decorative and functional features – the fronts are durable, easy to clean and, at the same time, allow the furniture to stand out.

Why invest in 3D milled fronts?

In times when the furniture market is saturated and competition is fierce, details matter. It is the finish of the fronts – their structure, depth and visual effect – that often determines whether a customer will choose a particular collection. 3D milling allows you to create fronts that not only look good, but also inspire and leave a lasting impression.

The main benefits of using 3D milled fronts:

Distinguishing your collection

The 3D structure immediately sets your furniture apart from smooth, flat pieces. This added value is visible at first glance – ideal for premium lines or designer editions.

Stylistic richness

Milling allows you to combine classic and modern styles. The designs can be adapted to the style of the interior – from Scandinavian simplicity, through Japandi, to Art Deco or industrial.

The possibility of creating original designs

3D fronts are the perfect canvas for designing unique collections. Melaco offers not only ready-made profiles, but also the possibility of MTO projects for contract customers, so that every manufacturer can have their own distinctive design.

Versatile application

Milled fronts are perfect for a variety of spaces:

- kitchens and dining rooms,

- living rooms,

- offices and reception areas,

- bathroom and children’s furniture.

Increased visual and sales value

Furniture with decorative milling is perceived as more exclusive. For the end customer, it is a detail that justifies a higher price. For the manufacturer, it is an opportunity for a higher margin.

Technologies that enable 3D milling: MELAFOL and MicroMilling™

For 3D fronts to impress with their precision and durability, you need not only the designer’s vision, but also the technology to make that vision a reality. At Melaco, we use two modern production lines that allow us to create fronts with a distinctive structure and high-quality finish: MELAFOL and MicroMilling™.

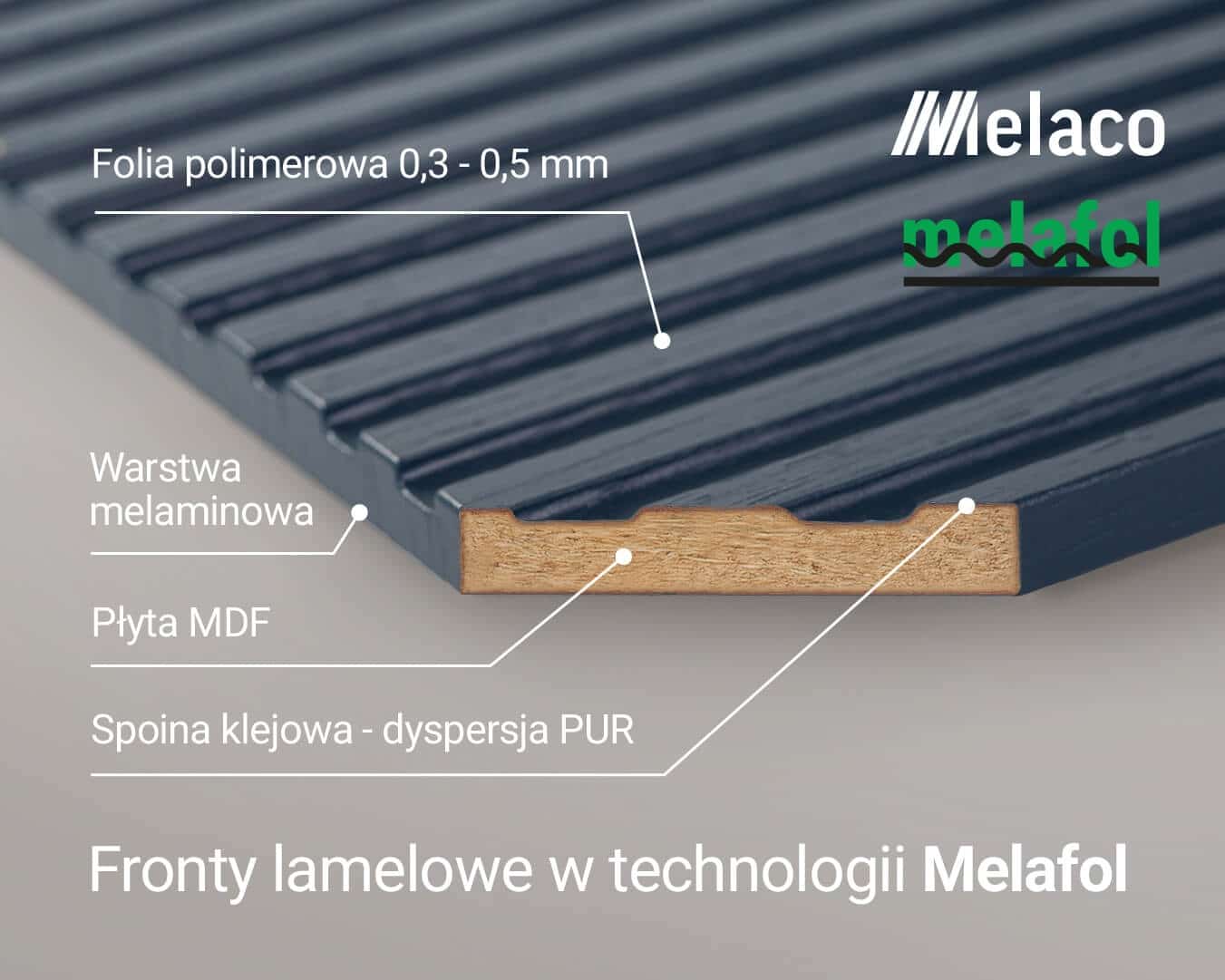

MELAFOL – proven technology for 3D fronts

This is a production line based on the vacuum pressing process. It involves the precise milling of MDF boards, which are then covered with a polymer film that perfectly reproduces every detail of the structure. MELAFOL offers:

- the possibility of deep, decorative milling,

- various types of film: matt, gloss, wood-like and modern structures,

- high repeatability – ideal for series production,

- resistance to mechanical damage and moisture.

MELAFOL technology is particularly popular among manufacturers of kitchens, children’s furniture and room collections, where both durability and aesthetics are important.

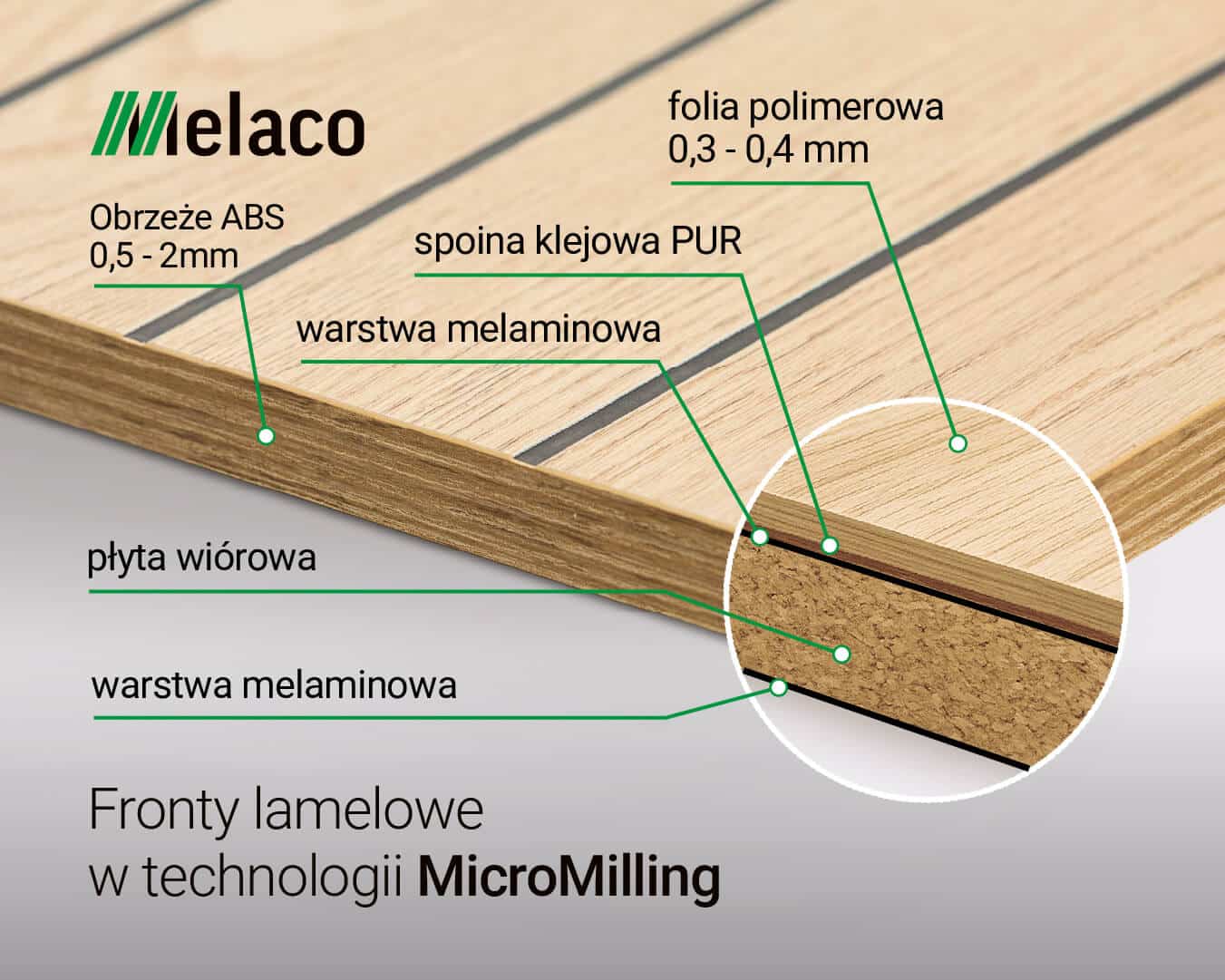

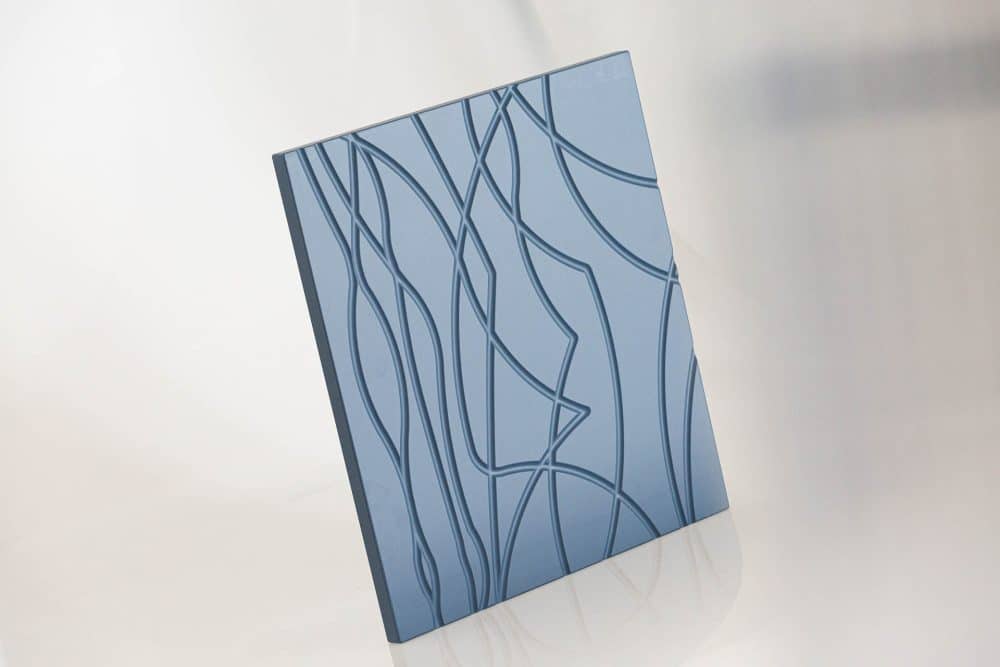

Micro Milling™ – precision down to 75 microns

This is an innovative plate milling technology in which the polymer film layer (e.g. PET) covering the surface is partially milled away with micrometric precision. Micro Milling™ offers:

- ultra-thin lines and complex patterns,

- a ‘light drawing’ effect – depth visible from different angles,

- the possibility of creating both geometric and organic forms,

- ideal for modern, minimalist furniture collections.

MicroMilling™ allows you to combine design with functionality – the structure is subtle yet distinctive, and the fronts remain fully resistant to wear and tear.

Examples of structures and applications

MELAFOL and MicroMilling™ technologies offer enormous design possibilities – from delicate, subtle lines to bold, geometric patterns. At Melaco, we have developed a collection of structures that work well in both modern and more classic interiors.

MELAFOL

MICRO MILLING™

Create fronts that stay in the memory

3D milling is not just a trend – it is a tool that allows you to really make your furniture collection stand out and give it a unique character. Thanks to MELAFOL and MicroMilling™ technologies, you can create fronts that engage the eye and touch, emphasise the style of the interior and show that your brand focuses on design, quality and precision.

Would you like to design your own structure? Or maybe you are looking for a ready-made design that will work well in your furniture line? Contact our team – we will show you how to harness the potential of milling in your collection.

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist