The DIY (Do It Yourself) trend has entered the furniture industry for good – and is strengthening its position every year. Customers do not want to waste time having furniture assembled by professionals or struggling with instructions full of screws and tools. They want to unpack, assemble – and enjoy the result in a matter of minutes.

Is this possible? Yes, if you use technology that really makes life easier. This is exactly what Flick&Click™ offers – a system of furniture components based on Threespine® tool-free assembly technology that is changing the way we design, manufacture and use furniture.

In this post, we will show you how tool-free assembly technology meets the needs of today’s market and what advantages it can offer furniture manufacturers who are thinking about the future.

The DIY market – expectations of modern customers

Just a few years ago, DIY furniture assembly was mainly associated with IKEA-style instructions, a bag of screws and several hours spent on your knees. Today, this is changing. The new consumer – conscious, busy and demanding – expects furniture assembly to be quick, simple and stress-free.

Why is the DIY trend growing so rapidly?

- Convenience – not having to hire a specialist saves time and money.

- Time – consumers want to unpack a piece of furniture and have it ready in a few minutes, without instructions like those found in an engineering manual.

- E-commerce and flat-pack furniture – more and more purchases are made online, which means that effective packaging and easy assembly without professional tools are a must.

- New lifestyle – mobility, frequent moves, renting – all this means that furniture must be more flexible and easy to disassemble.

- Minimalism and self-sufficiency – more and more customers want to decorate their interiors themselves – quickly, cleanly and with satisfaction.

In response to these needs, furniture manufacturers can no longer rely solely on classic assembly solutions. The DIY market is not a niche – it is the standard for modern functional furniture production. And where speed and simplicity are required, there is no room for technological compromises.

Read also: Super-matt finishes in furniture – a trend that is here to stay →

What is Flick&Click™ and how does it work?

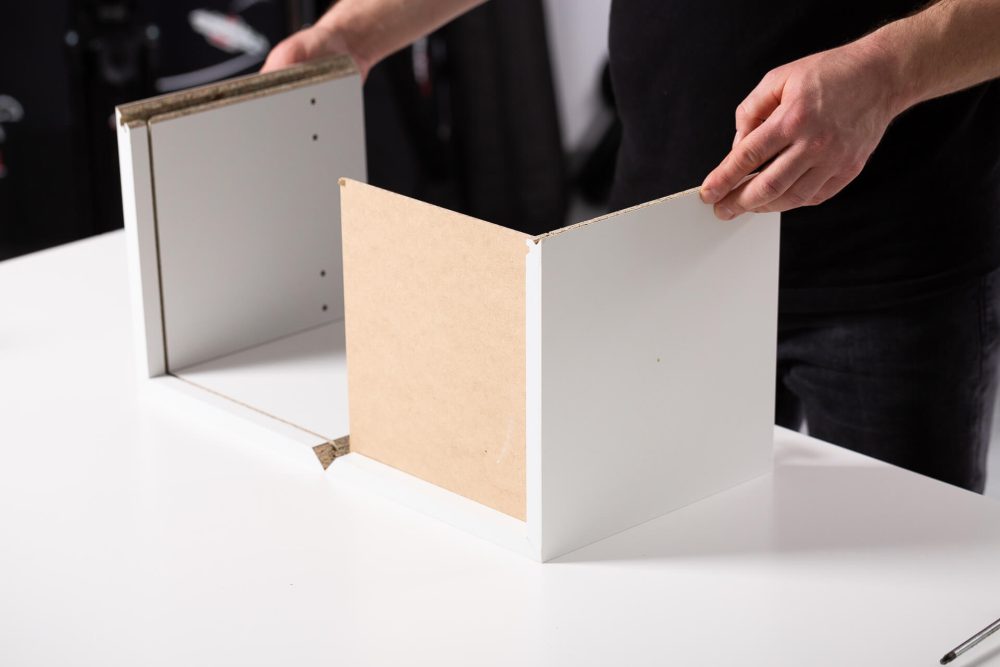

Flick&Click™ is a system of furniture components manufactured using Threespine® tool-free assembly technology. It allows for quick and tool-free connection of furniture components, eliminating the need for screws, dowels or other traditional assembly accessories.

How does it work?

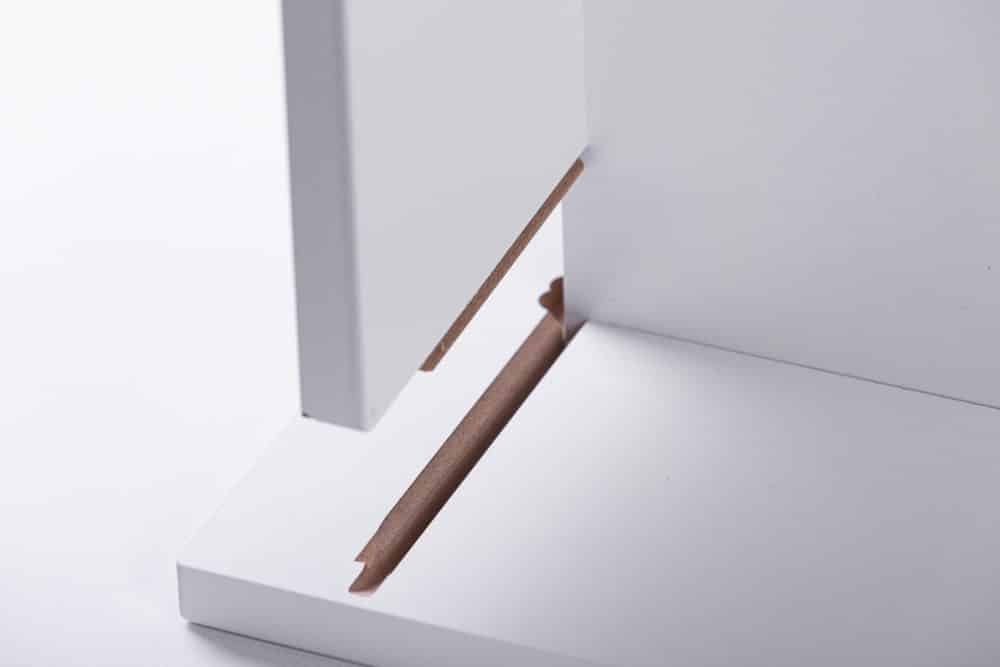

The Flick&Click™ system uses specially profiled edges on furniture components that allow them to be connected precisely and permanently with a simple push – the so-called ‘click’. This makes furniture assembly intuitive and quick, which is particularly beneficial for end customers who can assemble the furniture themselves without the need for tools.

Available connection options

Melaco offers two main types of connections in Flick&Click™ technology:

1. M-45° connection:

Connects corners at a 45° angle for an elegant and aesthetic finish.

Available in two versions:

- 4 x 5G: mechanical connections in four corners, designed for products intended for self-assembly by the end customer.

- 1 x 5G + folding: mechanical connection in one corner and the use of folding and assembly glue in the others, ideal for quick assembly both in the furniture factory and by the end user in the case of small furniture.

2. CORNER90 connection:

- Connects corners at a 90° angle, enabling not only assembly but also quick and tool-free disassembly of furniture.

- Used in the production of furniture bodies, drawers and other elements where easy assembly and disassembly are important.

- Additionally, this connection has been enhanced with the option of using a latch in the rear walls and bottoms of drawers, which increases the rigidity of the furniture and prevents the drawer bottom from falling out.

Flick&Click™ technology can be used on a wide range of materials, such as chipboard, MDF, plywood and solid wood, and in various finishes, from matt to high gloss. This allows furniture manufacturers to create products tailored to individual customer needs, while benefiting from quick and easy assembly.

Benefits for the end user

Although Flick&Click™ technology was designed with furniture manufacturers in mind, its true potential is revealed in the hands of the end user. It is the customer – the person who unpacks, assembles and uses the furniture every day – who feels the biggest difference.

Why will customers appreciate furniture with Flick&Click™?

Assembly without tools and frustration

No screws, bolts, Allen keys or parts to lose – just click. The user does not need to read complicated instructions, does not need help from another person or specialised equipment.

Time savings

The furniture can be assembled in as little as 5 minutes – literally. This is a huge advantage in times when ‘fast’ means ‘better’. Flick&Click™ furniture fits in with the pace of modern consumer life.

Greater satisfaction with the purchase

The customer feels that they have assembled the product themselves – without stress, without mistakes, without calling a friend with a drill. This builds a positive experience with the brand and increases the chances of recommending it to others.

Aesthetic, durable connections

Thanks to the precisely engineered design of the system, the assembled furniture is solid, stable and looks professional – with no visible fasteners or protruding screws.

Mobility and flexibility

The CORNER90 system also allows for easy disassembly. It is the perfect solution for people who move frequently or furnish temporary interiors, such as rented flats or offices.

Benefits for furniture manufacturers

Flick&Click™ technology is not only convenient for end users – it also offers real production and logistical advantages for furniture manufacturers. It enables process optimisation, cost reduction and the creation of innovative products that stand out on the market.

Why implement Flick&Click™ in production?

Fewer components = lower costs and faster assembly

Instead of multiple metal fittings, screws or hinges, there is one integrated system. This means fewer stock items, simpler packaging of sets and no need to complete accessories.

Lower carbon footprint

Lighter packages and no additional components mean less material consumption and lower emissions during transport. This is not only an environmental benefit, but also a marketing advantage – more and more customers expect sustainable solutions.

Reduced assembly time at the factory or at the customer’s site

Flick&Click™ enables the implementation of flat pack or pre-clicked solutions, depending on the business model. Assembly can be carried out at the end customer’s site or on the production line in just a few minutes.

Greater added value for the product

The Flick&Click™ system is more than just a way of joining boards – it is a technology that can be communicated as an advantage. For the customer, it means convenience, for the manufacturer – a modern image and a higher level of offering.

Adaptation to different formats and materials

At Melaco, we offer ready-made components with Flick&Click™ technology made of MDF, chipboard or plywood. They can be easily integrated into various furniture collections: from modern modular systems to children’s, kitchen and office furniture.

Read also: How to optimise furniture production with ready-to-assemble components? →

The potential of Flick&Click™ in furniture collection design

Flick&Click™ technology not only changes the way furniture is assembled – it changes the entire approach to design. It gives designers and manufacturers completely new tools to create collections that are more functional, mobile and tailored to modern lifestyles.

What does Flick&Click™ offer in practice?

Modular furniture design

The system allows elements to be easily connected and separated, which fits perfectly with the concept of modular furniture. Customers can decide on the layout and configuration themselves, for example by adding another segment to a cabinet or bookcase without having to dismantle the entire structure.

Collections dedicated to e-commerce

In the age of online sales, more and more brands are looking for furniture that can be safely packed, easily shipped and even easier to assemble. Flick&Click™ eliminates the problem of lost parts, damaged connections or failed assembly.

New possibilities for rentals and mobile spaces

Furniture that can be assembled and disassembled without damage is ideal for rented interiors, co-working spaces, mobile offices and students. Flick&Click™ allows you to create furniture that follows the user’s lifestyle.

Showroom and display concepts

Quick assembly and disassembly are also an advantage in retail – manufacturers and distributors can quickly prepare displays, rearrange exhibition space and test new product layouts.

Freedom in aesthetics and format

Flick&Click™ does not impose any style – it can be used in simple, modern furniture as well as in more advanced designs with milled fronts, unique structures and unusual formats.

Ready in 5 minutes. Ready for the future.

Flick&Click™ is more than just innovation – it is a concrete response to the needs of today’s furniture market. For the user, it means convenience and simplicity. For the manufacturer, it means savings, modernity and a competitive advantage.

If you want to create furniture that impresses not only with its design but also with its functionality, please contact us. We will show you how to implement Flick&Click™ in a modern furniture collection.

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist