This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

MICRO MILLING™ – what is it?

The MICRO MILLING™ technology consists of precise surface treatment of the COMPLETE SKIN board. However, to achieve the intended effect, its front is covered with foil or veneer with a thickness of 200 μm to 300 μm. The outer layer is milled according to the design. Specialized copying units with electronic thickness measurement in real time and diamond cutters are used for processing.

Machining in the MICRO MILLING™ technology is carried out in the depth range of 50 μm-100 μm. In this process, we use specialized Alphacam software, which allows importing and processing into machine codes very complex graphic designs made by our designers or received from the client.

In the MICRO MILLING™ technology, we make fashionable minimalist lines, modern geometric patterns and any patterns chosen by the customer. We use it in the production of the kitchen, bathroom and room furniture components, sliding wardrobes, as well as in interior design elements and elements of public utility facilities, commercial facilities and hotels.

MICRO MILLING™ – our inspirations

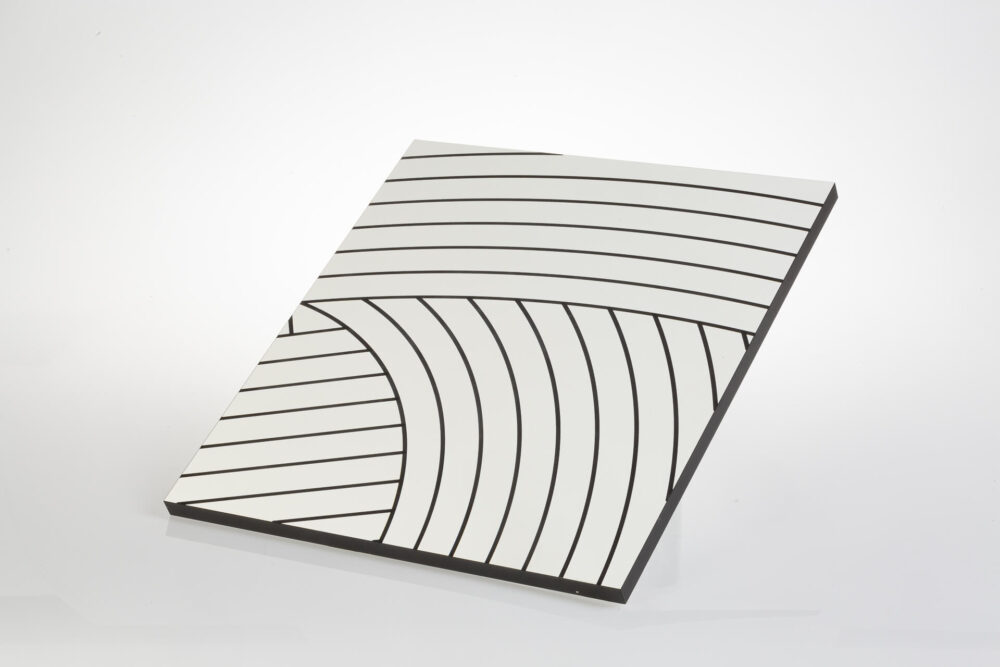

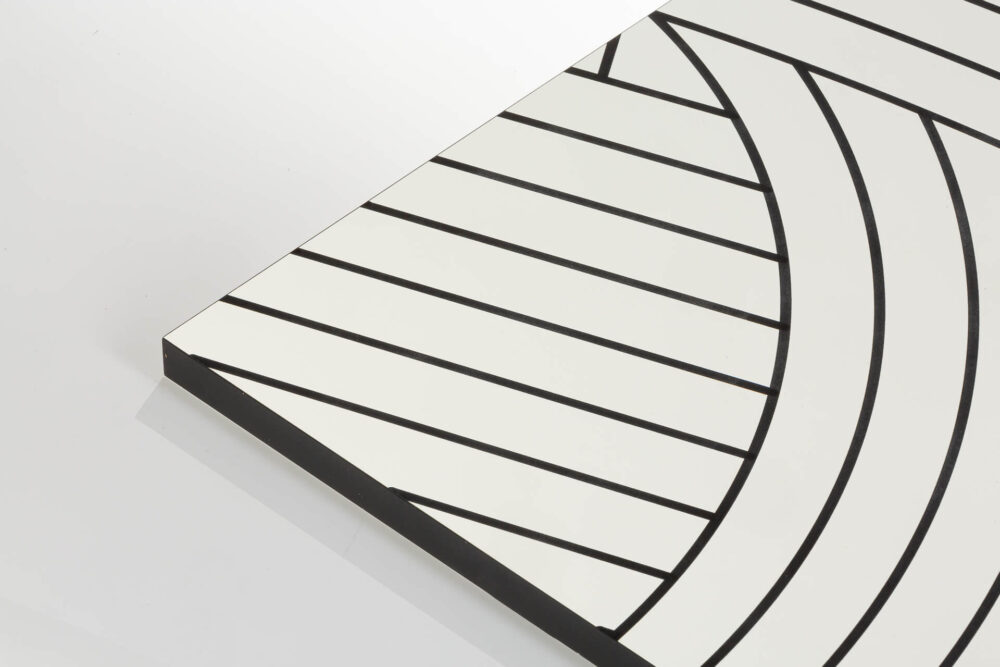

Thanks to this process, it is possible to apply any design, both in the form of geometric patterns and arcs or circles. The black and white pattern with an unusual arrangement proposed in the photos below will allow you to create a coherent and eye-catching furniture collection, for example a kitchen collection, where the fronts will perfectly combine into an interesting, three-dimensional pattern.

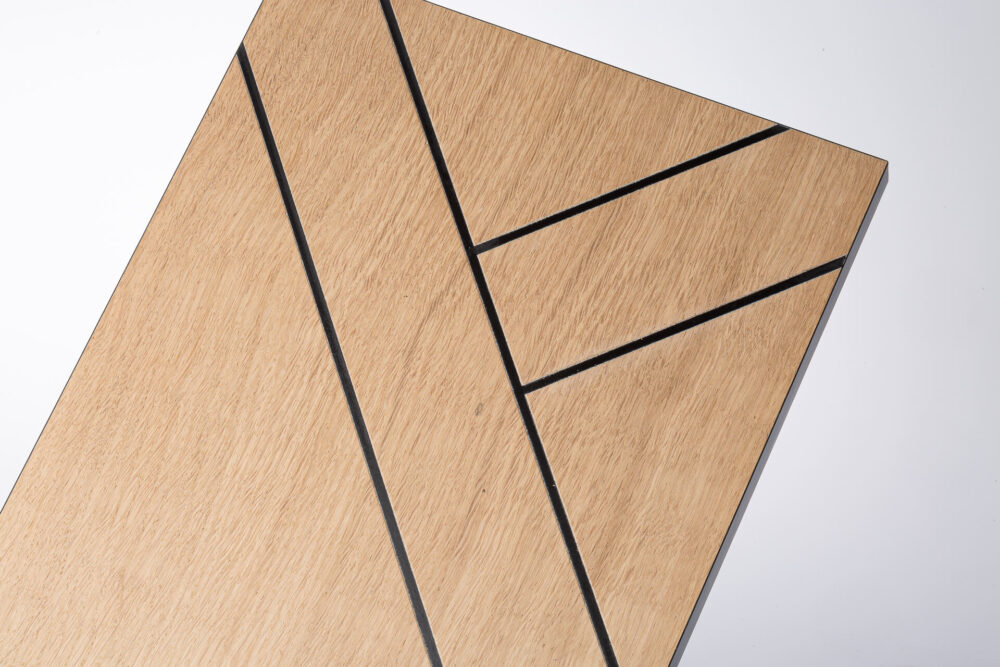

An interesting effect is also offered by the combination of a warm shade of wood with black. Among our projects in this version, there are both minimalist, delicate patterns and more expressive designs. The first one is a simple front with vertical lines, imitating the popular lamella pattern. The edges of the board are the same colour as its surface, which gives it lightness.

In the next version, a geometric, very economical pattern and black edges were used. Thanks to this, the front gained a very elegant finish, which will be perfect for any modern interior.

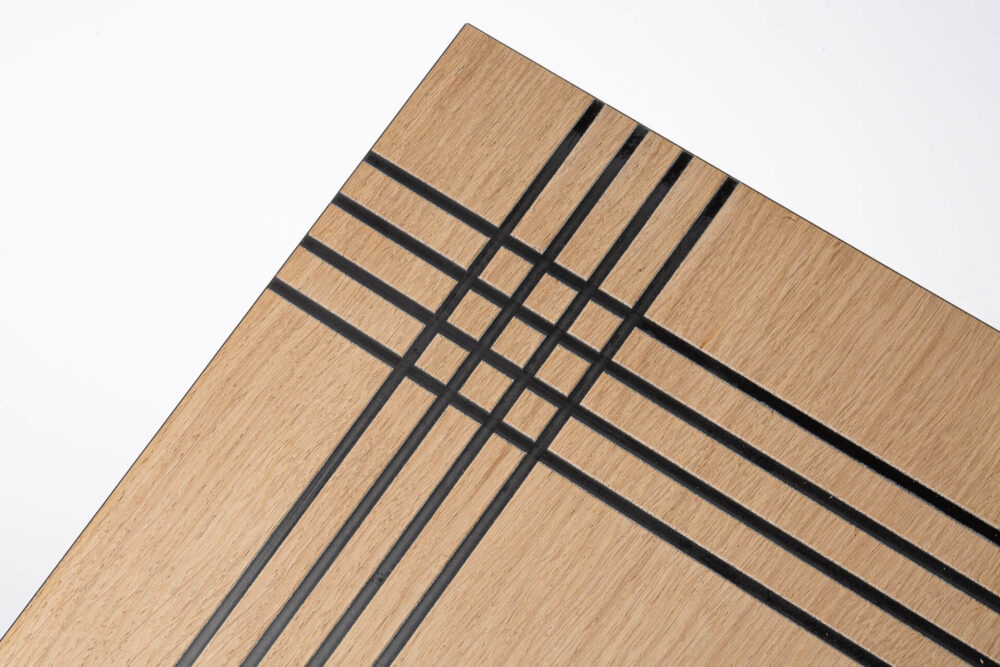

The MICRO MILLING™ technology also allows the pattern to “intersect”, as shown in another implementation. In this case, the transverse lines overlap symmetrically with the vertical ones, creating an interesting checkered effect.

The MICRO MILLING™ technology can be used on boards of various sizes, including narrower ones, used as furniture sides or as a finishing element. This gives additional aesthetic value and makes the collections more distinctive.

COMPLETE SKIN furniture boards – advantages

Surface finishing using the MICRO MILLING™ technology is used on COMPLETE SKIN furniture boards and ribbons. They are made of laminated MDF or chipboard and covered with polymer films from reputable and recognized suppliers in the HOT MELT LAMINATION technology. The edges of the components can be finished on one or both sides in postforming technology.

COMPLETE SKIN furniture boards and ribbons are resistant to high temperatures and moisture thanks to PUR adhesives, which is why they can be installed next to ovens and cookers. They work well as various elements of furniture, from the fronts of drawers to the doors of wardrobes. They are often chosen by manufacturers of kitchen, children’s, room, bedroom and office furniture.

Our technologies are at your disposal

If you want to use our proven solutions for your own furniture collections, please contact us. We offer consulting in the selection of technology, project preparation and production implementation.

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist