This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Technology of veneering narrow planes and panels

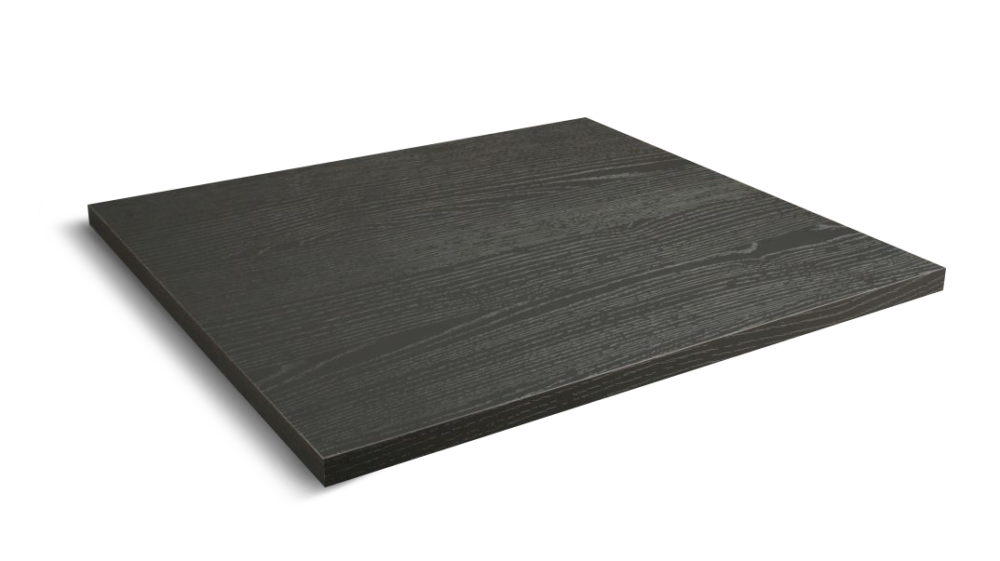

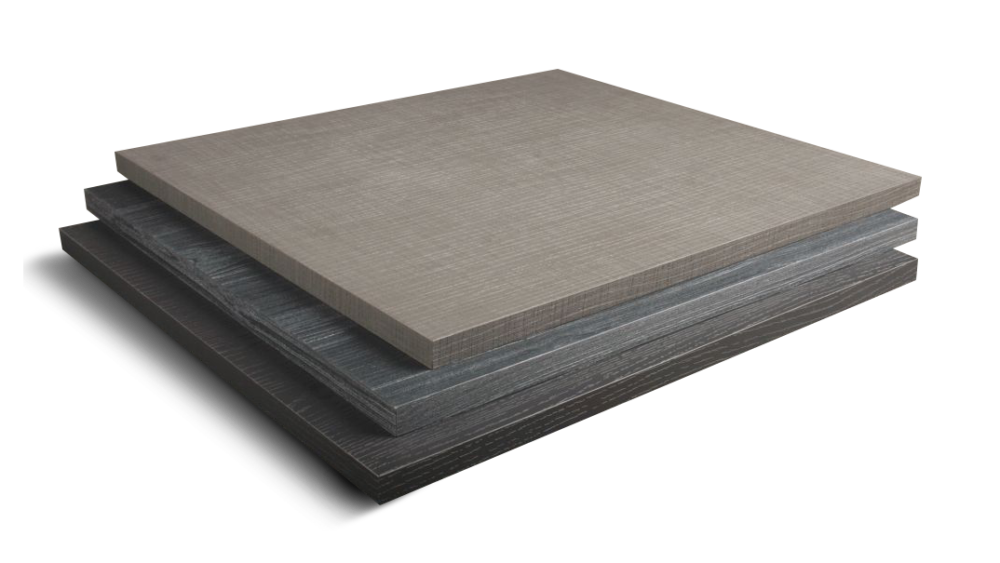

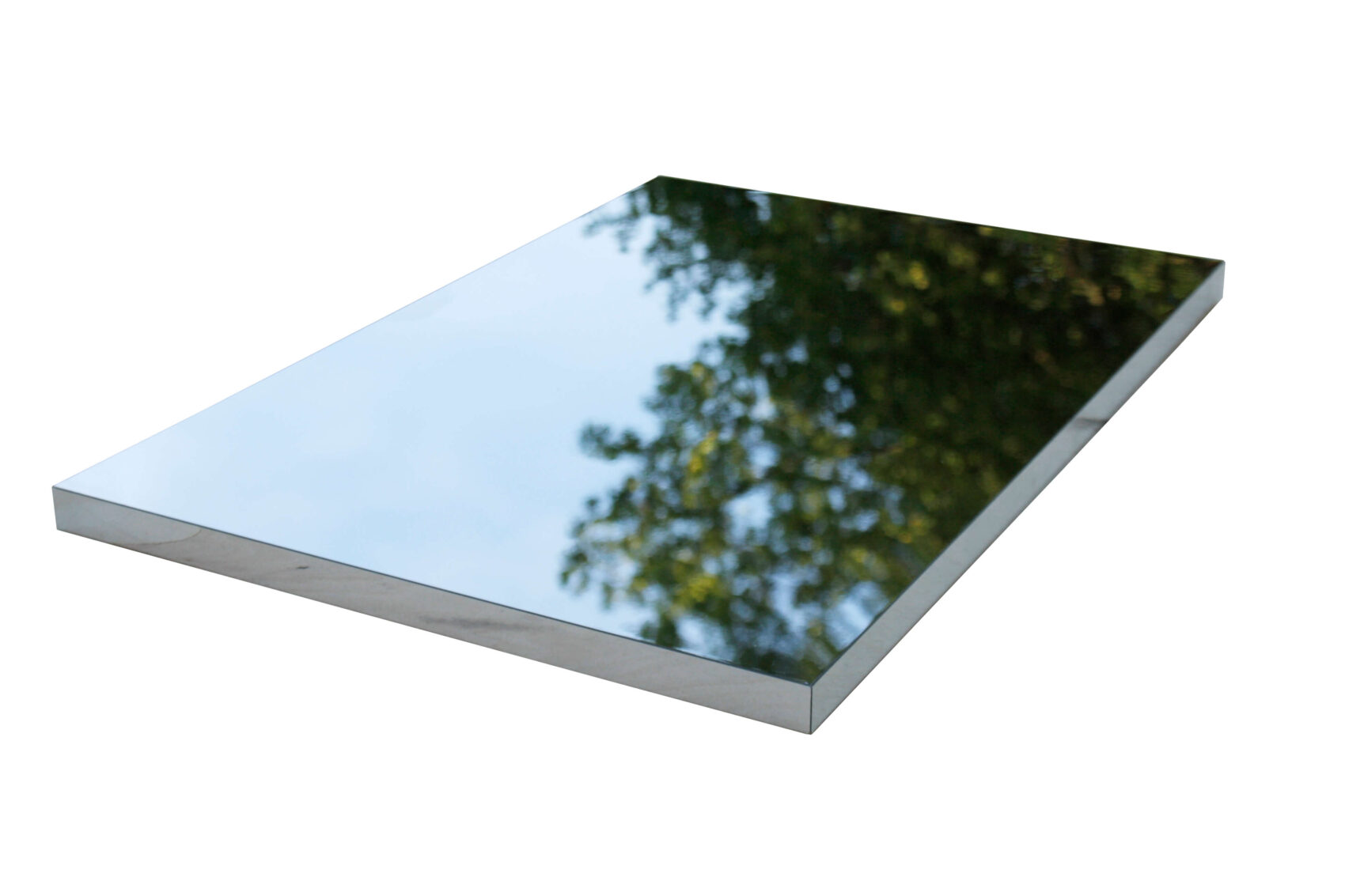

Particle boards and MDF boards, which we use in production, are covered with high-quality polypropylene films of selected colors or patterns. Their advantage is not only the aesthetic appearance, but also the properties that increase the parameters of each manufactured element. For foil application, we use the technology of continuous lamination – HOT MELT LAMINATION – with the use of durable PUR glue.

Thanks to the very even application of a controlled minimum weight of the reactive adhesive to the board with a roller, it gains perfect smoothness and exceptional quality. The adhesive joint is highly resistant to moisture and elevated temperature, which means that our furniture elements are often used in the production of kitchen and bathroom furniture. They are also perfect for bedroom and room furniture, guaranteeing high durability and reliability for years.

Find out more: HOT MELT LAMINATION technology – for durable furniture

Pre-treatment system

Before gluing, each element undergoes pre-treatment, during which the element is formatted to the given net dimensions. In this process, we use diamond cutters that are characterized by exceptional machining accuracy. The MDS system ensures the accuracy of machining with the tolerance of the workmanship in the range of the linear dimension +/- 0.1 mm, the angle +/- 1⁰.

The processed plate thickness range is from 8 mm to 60 mm. The range of the thickness of the processed edge is from 0.3 mm to 2 mm.

For finishing the edge, we use a system with an automatic magazine of cutting tools, including:

- pre-cutters and finishing cutters,

- so-called rounders for processing corners,

- so-called profile scrapers for finishing the treated surface,

- edge polishing brushes and polishing fluids,

- heaters for vitrification of the ABS treated surface, enabling the removal of whitening created after machining.

Technology of veneering narrow planes and panels – advantages and parameters of the product

The carefully developed process of veneering narrow planes and panels allows us to provide customers with excellent quality products, which are part of a furniture collection. They are characterized by:

- waterproof glue joint, enabling the use of elements also in rooms exposed to moisture;

- high thermal resistance of ≥120⁰C;

- no visible glue line, which ensures an elegant and aesthetic finish of each element;

- high precision of the edge finishing and a wide range of its thickness;

- high dimensional accuracy of the pieces.

The technology of veneering narrow planes and panels, which we use in Melaco, provides us with high production flexibility, and thus – also high efficiency thanks to the full automation of the process. We are also able to implement small production series in this way.

This technology offers our clients a wide range of materials for the application of the edges: PVC, ABS, PP, PET, veneer, melamine. Application of the edgeband is also possible without prior application of the primer. In the event of difficulties with the selection of the appropriate material, we provide our expert support.

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist