The expectations of customers – both individual and institutional – are rapidly evolving. It is no longer just the appearance that counts, but also how the product was manufactured, what it was made of and whether its production had an impact on the environment. More and more interior designers, investors and manufacturers are looking for solutions that combine aesthetics with responsibility.

At the same time, sustainable development is no longer just an image value – it is becoming a tool for building a real competitive advantage. It translates into easier exports, access to conscious customer groups and, ultimately, better business.

Is eco-design the future of furniture? Or is it already the present? In this article, we will show that investing in solutions that are in line with the idea of sustainable development is not only the right direction, but also a profitable strategy.

What does ‘sustainable’ mean in the furniture industry?

The concept of sustainable development is used very broadly in the industry – from natural resources to reducing emissions and optimising processes. In practice, this means conscious design, production and logistics decisions that minimise environmental impact while increasing product value and functionality.

In furniture manufacturing, sustainable design includes, among other things:

- Choice of materials – preference for natural or recycled raw materials, certified according to international standards (such as FSC®).

- Durability and long product life cycle – furniture that does not wear out quickly, does not need to be replaced and does not generate waste.

- Easy assembly and disassembly – furniture is increasingly being designed so that it can be easily disassembled, transported and reassembled without the use of adhesives or metal fasteners.

- Safe chemicals and low emissions – components must meet strict emission standards (e.g. DIN EN 16516) to be safe for use and the environment.

- Process and transport optimisation – smaller packaging, fewer parts, lighter components = lower carbon footprint in logistics.

Importantly, sustainable design does not mean compromising on appearance. Quite the contrary. Aesthetics based on nature-inspired materials, high-quality finishes and refined details are now one of the main criteria for choosing premium products.

Read also: European Green New Deal in Melaco – how we care for the environment →

Why is it profitable for the manufacturer?

Sustainable design is no longer just a matter of aesthetics or ideology – it is increasingly becoming a business strategy that brings real benefits to furniture manufacturers.

Brand and collection recognition

In a world where it is increasingly difficult to attract customers’ attention, ‘green’ values can be the key to building a competitive advantage. Furniture made with care for the environment is more likely to gain recognition from interior designers, showrooms and public investors.

Better cooperation with designers and partners

Architects increasingly have to meet stringent environmental requirements, especially for commercial, hotel and office projects. A manufacturer who supplies certified, durable and environmentally friendly components becomes a valuable partner for them.

Access to demanding foreign markets

In markets such as Scandinavia and the Netherlands, sustainable development is the norm, not an add-on. Products with FSC® certification, low formaldehyde emissions or made from bio-based materials are better perceived and more quickly accepted by retail chains.

Better image and CSR compliance

More and more companies, including those in the furniture industry, are building their strategies around transparency and responsibility. Working with a supplier that focuses on sustainable technologies and materials is an important part of these efforts.

Long-term savings

Less waste, fewer complaints, greater durability and simplified logistics all mean lower operating and production costs. Ecology is not only profitable – it actually increases efficiency.

Read also: Furniture formats – how Melaco supports manufacturers in efficient production →

What eco-friendly solutions does Melaco offer?

At Melaco, we believe that environmental responsibility begins at the design stage and ends only when the product reaches the customer. That is why we implement specific solutions that genuinely support sustainable development – both in terms of materials and technology. Here are some examples of solutions we use to support our partners’ environmental policies.

MELAFOL fronts with FLORA film

One of our flagship eco-friendly products is MELAFOL fronts covered with innovative FLORA film. This material is made of:

- salt (57%),

- bioethylene derived from pine oil (43%).

Importantly, the ethylene used comes from certified second-generation biomass, which does not compete with the food chain. The result?

- Up to 90% less CO₂ emissions than traditional PVC films.

- 100% production in the European Union.

- The same durability and aesthetics as standard films.

R-PET – a second life for material in an aesthetic form

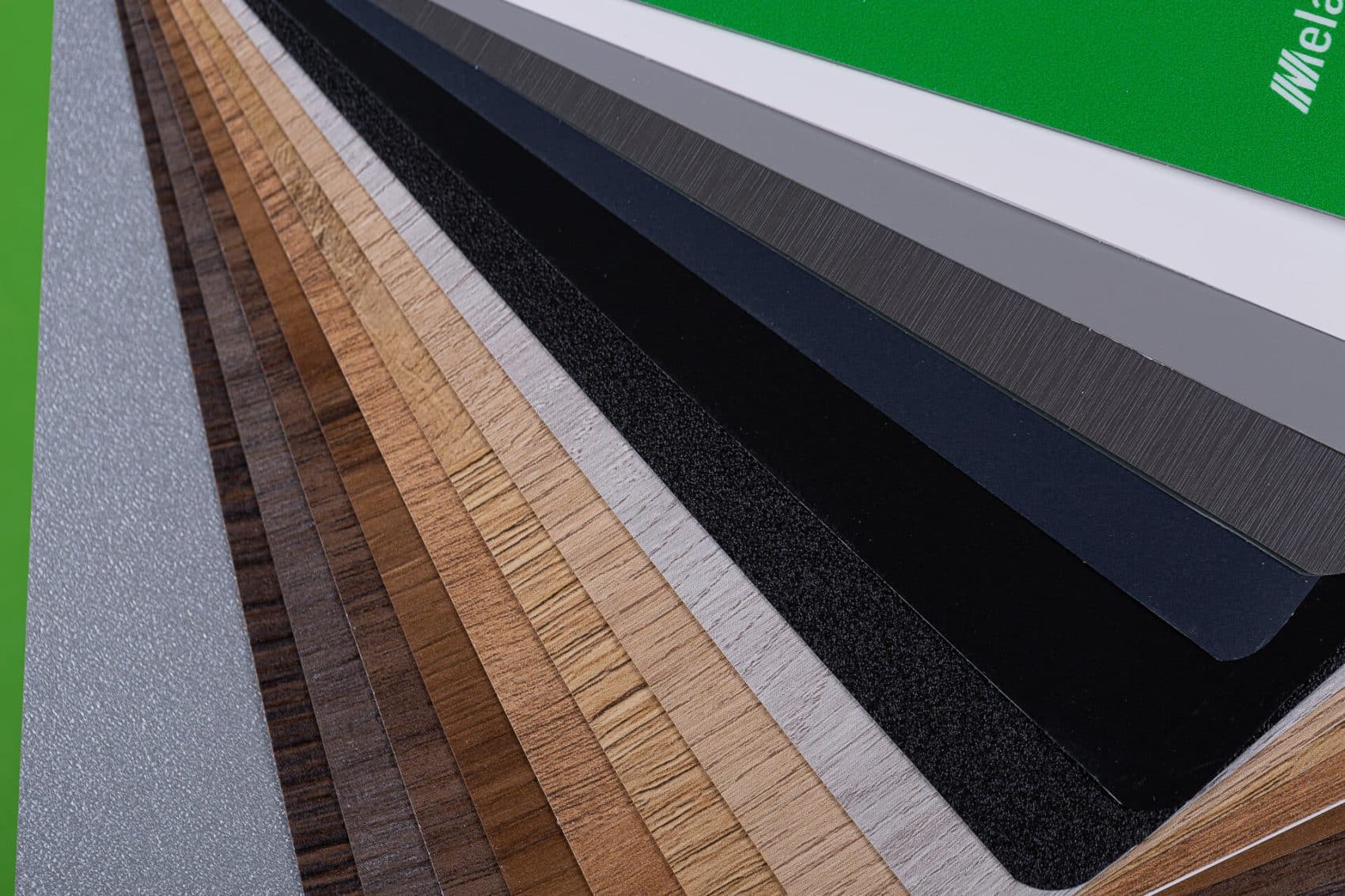

At Melaco, we also use R-PET films, which are made from recycled plastics – a perfect example of recycling in practice.

The Comfort Oak finish, inspired by the structure of natural oak, offers not only a unique texture but also a rich colour palette. It is the perfect choice for collections that combine an eco-friendly approach with attractive appearance and durability.

PET laminate – aesthetics without compromise

PET laminates are another sustainable design option – they are a modern alternative to standard PVC films. This solution allows you to maintain a high level of aesthetics and mechanical resistance while reducing the negative impact on the environment. They are ideal for the production of fronts and panels that have to meet market requirements without compromising on quality.

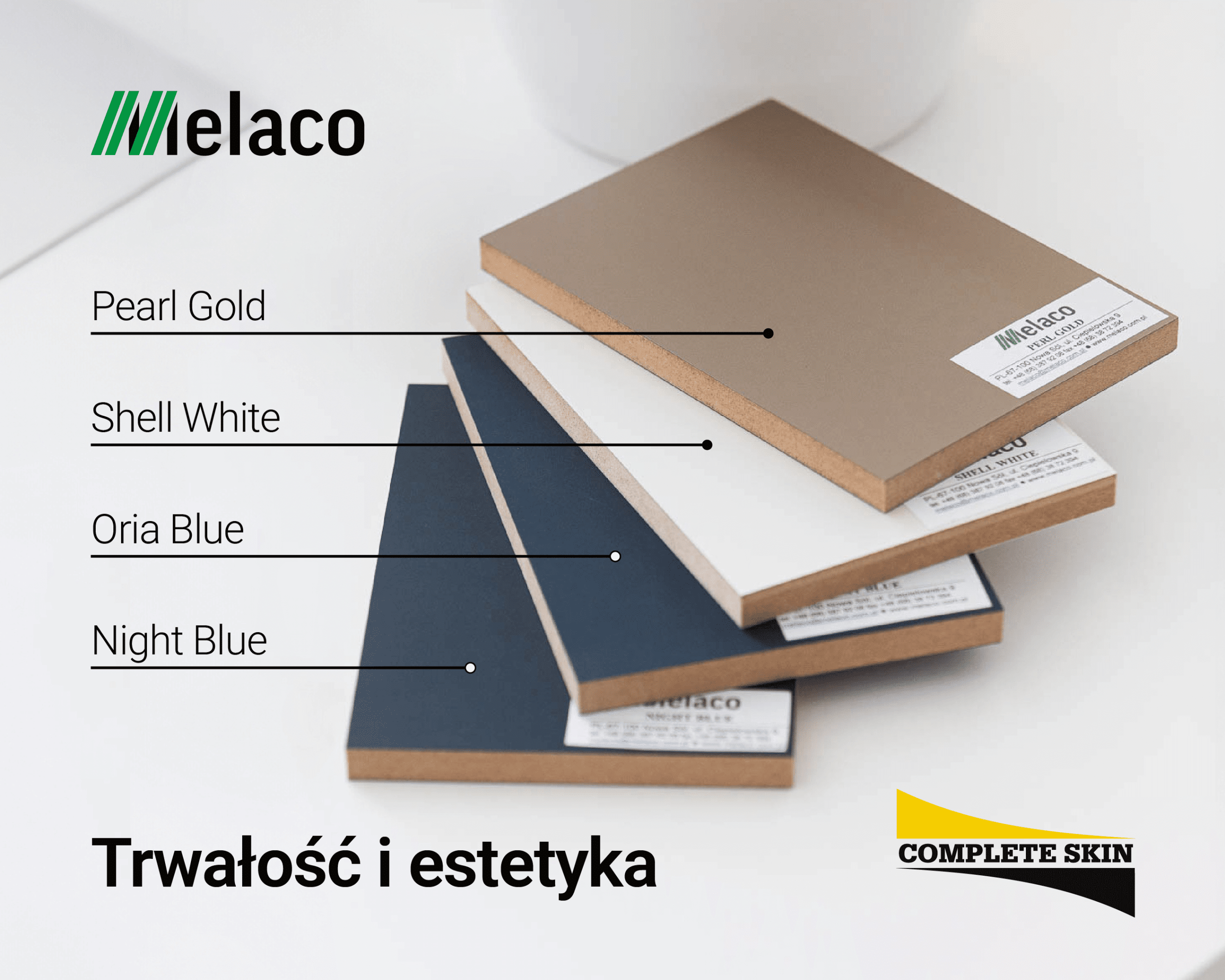

An example of this are STAR DUST furniture boards with a matt finish and an elegant glitter effect, which not only meet ecological standards but also ensure high comfort of use. They offer high resistance to elevated temperatures and moisture thanks to the use of HOT MELT LAMINATION technology, and the anti-fingerprint effect prevents fingerprints from remaining on their surface.

The boards can be used for the production of fronts, bodies or decorative elements. The STAR DUST collection is available in six universal colours: Shell White, Pearl Gold, Space Black, Sky Blue, Night Blue and Pearl Bronze.

Lamella structure – wood in a new guise

Lamellae are becoming increasingly popular as an interior design element, but at Melaco we have gone one step further by creating a lamella structure that replicates the effect of wood in a more sustainable and reproducible way.

Thanks to MELAFOL technology and precise MICRO MILLING™, we achieve elegant, rhythmic surfaces. This is the perfect solution for fronts and panels that need to look natural but be more resistant and easier to produce.

Flick&Click™ – simpler, faster, more environmentally friendly

Not only materials, but also the method of assembly can support sustainable development. The Flick&Click™ system, based on Threespine®* tool-free technology, allows furniture to be assembled quickly without the use of screws or metal fasteners.

This is not only convenient for the end user, but also results in real savings in logistics and production – smaller packages, lower carbon footprint, no additional components. For manufacturers, this means less waste, and for the environment – fewer emissions and easier recycling.

*The THREESPINE® word mark and logo are registered trademarks owned by VALINGE INNOVATION AB, and any use of these marks requires a licence.

FSC® certificates – responsible raw materials

All MDF boards, chipboards and plywood used by us come from FSC® certified sources. This guarantees that the wood used in production comes from responsibly managed forests – with respect for the environment, local communities and workers’ rights.

Recycling and circular economy

We use post-production recycling procedures in our production – waste is returned to the manufacturer for processing. In this way, we reduce the amount of primary raw materials and make maximum use of what has already been produced.

Process automation and optimisation

We implement modern technologies and automation of production processes, which allows us to:

- Increase energy efficiency.

- Reduce raw material consumption.

- Minimise waste.

An example is the use of packaging robots, which consume less packaging materials, and production management systems that optimise energy and raw material consumption.

Efficient logistics and smaller packaging

Thanks to compact packaging and transport optimisation, we reduce the carbon footprint of our products. Smaller packaging is not only beneficial for the environment, but also means lower transport costs for our customers.

Find out more about our pro-environmental initiatives in the article: Sustainable development in furniture manufacturing. What is it and what are its benefits? →

Thanks to these measures, Melaco not only meets the highest standards of sustainable development, but also offers its business partners real benefits, such as:

- Market differentiation through environmentally friendly products.

- Access to new segments of environmentally conscious customers.

- Compliance with legislative and certification requirements.

If you would like to learn more about our solutions and cooperation opportunities, please contact us.

Design that speaks about values

Sustainability in furniture manufacturing is not just a ‘green’ addition to the product range – it is increasingly becoming the main message that brands want to convey to their customers. Today’s end customers are looking for products that offer more than just good looks: they want to know that what they are bringing into their homes has been made with respect for the environment and people.

At Melaco, we believe that design can be both beautiful and responsible. That is why we develop solutions that give designers and manufacturers real tools to achieve this. FLORA foil-finished fronts, COMPLETE SKIN boards with PET laminate, less-waste milled structures, Flick&Click™ systems – each of these elements helps to create collections that are not only fashionable but also conscious.

Because today, it is no longer just fashionable decors that are valued, but the history behind the material. The process from which it was created. And the decisions that were made along the way.

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist